Ameise®

Buying TipsBasic quality

Products reduced to the essentials

For light and occasional use

Good quality

Strong performance

Robust products for everyday use

Premium quality

For the highest load demands

Designed for continuous use

- 2 fork lengths available

- 3500 kg capacity

- Rubberised comfort handle protects against cold

8 Working days

- Sideways movement for enhanced mobility in tight spaces

- Robust quality thanks to welded sectional steel frame and reinforced tiller

- Durable, high-performance hydraulic pump with overload valve

8 Working days

- Electric lifting and lowering of the platform

- Fully variable hydraulic height adjustment

- External control unit with pushbuttons, key switch and emergency disconnect

8 Working days

- Simple handling of display pallets

- 250 kg capacity

- 1 fixed and 2 steering castors with wheel stop

8 Working days

- Ideal for longitudinal and transverse lifting of Euro pallets and lifting closed-boarded UK pallets

- Robust quality with 1000 kg capacity

- Loads can be raised via the tiller or foot pedal

8 Working days

- Electric drive function

- Up to 1,000 kg trailer load

- Flexible and versatile

10 Working days

- Ideal for heavy transport goods

- Movable thanks to 4 steering castors with wheel stops

- Tie-bars for connecting multiple conveyors

8 Working days

- Automatic quick lift (up to 100 kg)

- Single mast with 1600 mm lift height

- Small turning circle thanks to compact dimensions

8 Working days

- With foot pedal for hydraulic raising of the load surface

- Fully variable lowering via hand lever

- Folding handlebar

8 Working days

- Hydraulic lifting via tiller or foot pedal

- High-performance hydraulic pump made from high-strength steel

- Overload valve for long service life

8 Working days

- Foot pedal for easy lifting

- Fully variable lowering valve for precision manual lowering

- Chrome-plated handlebar

8 Working days

- Fork length of just 800 mm for use in tight spaces

- Light and handy size for easy transport in vehicles

- Ideal for transporting half, display and special pallets

8 Working days

- Multi-range display (0-200 kg in 0.2 kg, 200-500 kg in 0.5 kg, 500-2000 kg in 1 kg)

- Max. 0.1% deviation from measured weight

- Tare function, tare entry, summation with sequential numbering

8 Working days

- Hydraulic lifting via tiller or foot pedal

- High-performance hydraulic pump made from high-strength steel

- Overload valve for long service life

8 Working days

- Robust single-scissor lift platform truck with proven Ameise® quality

- 500 kg capacity

- Frame and scissors made from welded sectional steel

8 Working days

- Robust double-scissor lift platform truck with proven Ameise® quality

- 350 kg capacity

- Frame and scissors made from welded sectional steel

8 Working days

- Robust steel construction

- Capacity of up to 700 kg, depending on model

- Frame and scissors made from welded sectional steel

8 Working days

- Light, compact and available in different versions

- Movable thanks to 4 steering castors with wheel stops

- Tie-bars for connecting multiple conveyors

8 Working days

- Ideal for tight corners

- Movable thanks to 4 steering castors with wheel stops

- Tie-bars for connecting multiple conveyors

8 Working days

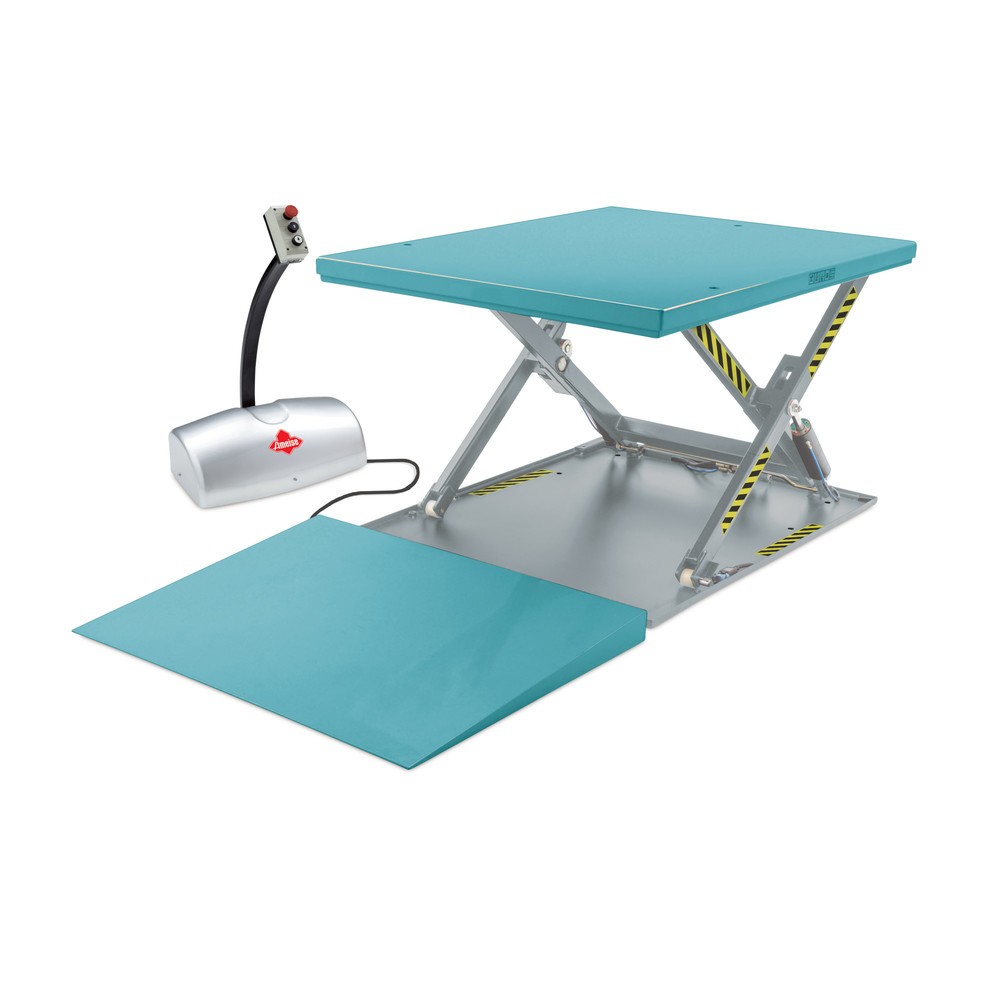

- Robust construction with stable scissor bracing

- U-shaped platform for pallet and forklift trucks

- With separate control unit

8 Working days

- Distance across forks of just 450 mm

- Durable high-performance hydraulic pump

- Reinforced tiller

8 Working days

- Hydraulic lifting via reinforced tiller or foot pedal

- High-performance hydraulic pump made from high-strength steel

- Overload protection for long service life

8 Working days

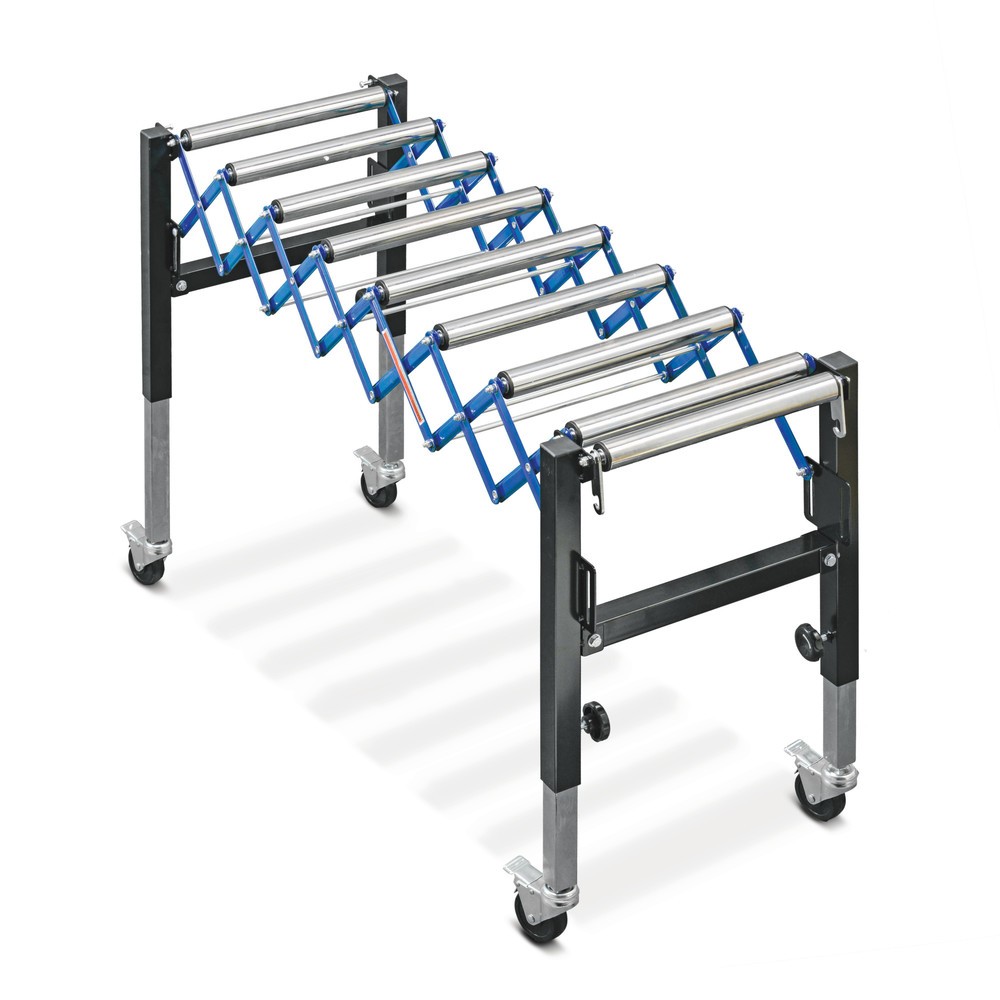

- Mobile accordion style mini roller conveyor with flexible routing

- Height-adjustable for ergonomic working

- Independently mounted plastic rollers for secure transport

8 Working days

- Maintains the set working height

- Enables ergonomic loading and unloading

- Automatic raising or lowering of the forks

8 Working days

A brand with tradition: reliable pallet trucks and stackers from Ameise®

Since Friedrich Jungheinrich registered the name "Ameise", the German word for "ants", for hand pallet trucks and trolleys in 1948, the Ameise® brand has been inseparably linked with the Jungheinrich success story. The first battery-powered pallet truck also appeared under this name in the same year. Solid, robust workmanship and reliable quality made the pallet trucks such a great success that Ameise® is still used as a synonym for pallet trucks today – irrespective of design and manufacturer.

Another breakthrough came in 1953 when Jungheinrich presented the first electric four-wheel forklift truck, the "Ameise 55" (A55), at the Hanover Fair. The revolutionary idea was that the operator sits on the truck and does not have to use their body strength to steer. With its compact design and small turning radius, the truck could also be used in narrow warehouses – which made it an absolute bestseller.

Since then, a lot has happened at Ameise®: from flexible hand pallet trucks to powerful electric pallet trucks to automated driverless transport systems, the Ameise® range has been constantly expanded with lifting and transport equipment that is as innovative as it is reliable.

1. What makes Ameise® equipment so special?

The brand name for the transport devices from the Ameise® product range was not chosen by chance. The industrious ant can move many times their own weight seemingly effortlessly and with great endurance – Friedrich Jungheinrich transferred these characteristics to his products. To this day, Ameise® stands for:

- Reliability and endurance: Thanks to high-quality materials and stable workmanship, Ameise® products are low-wear and made for long-term continuous use.

- Safety and comfort: Innovative technologies and designs ensure that daily work can be performed more easily and efficiently with Ameise® transport equipment. Both the physical relief and the safety of warehouse and production workers are always of utmost importance.

- Flexibility: Ameise® equipment is compact, easy to manoeuvre and available with different specifications (width, fork length, load capacity).

The secret of the Ameise® brand's success is that there is a suitable solution for the most diverse requirements and applications. This is because Jungheinrich has always been in close contact with its customers and focuses on their needs when developing new transport equipment. This applies not only to matching the latest storage strategies and production technologies, but also to the good price-performance ratio for which Ameise® is known. To this day, customers benefit from the nationwide customer service, reliable spare parts supply and flexible leasing options for Ameise® products.

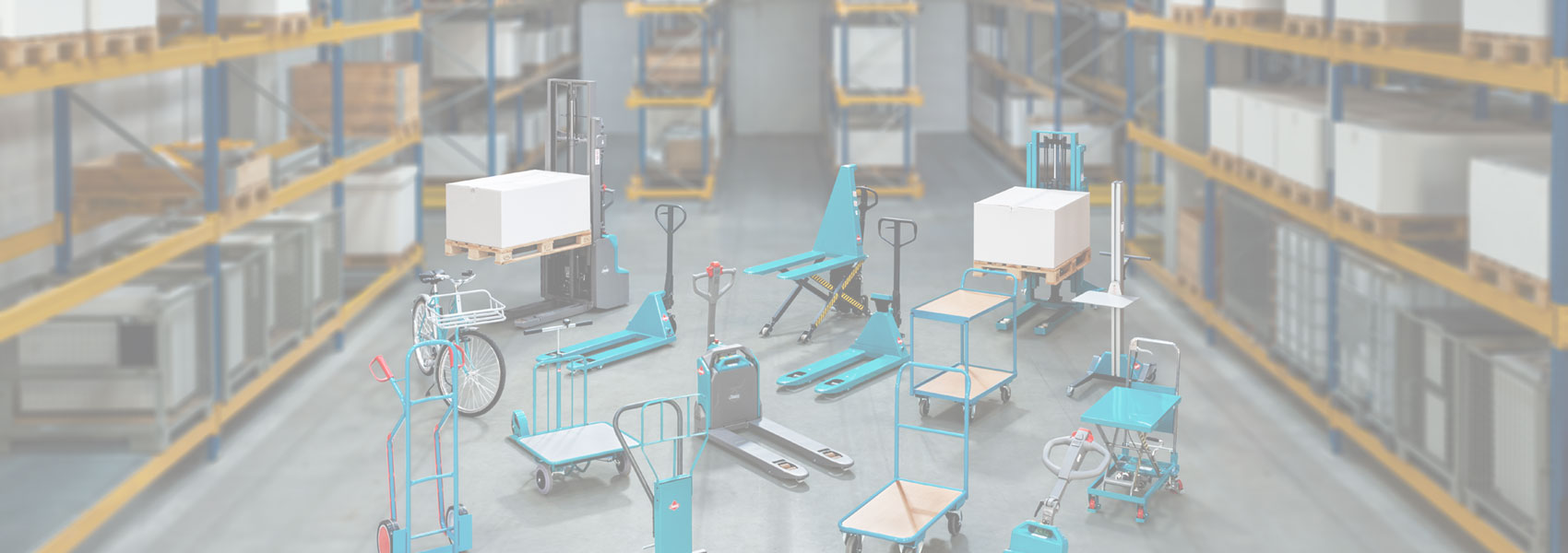

2. Ameise® at Jungheinrich PROFISHOP

You want to update your warehouse transport technology and are looking for robust equipment for long-term use? In the Ameise® range at Jungheinrich PROFISHOP you will find all the lifting and transport equipment from the tried and tested traditional brand including:

3. Other products available from Ameise®

In addition, there are other items from Ameise® that can help you optimise your logistics and transport processes: these include electric tugs and conveyor tables, among others. All Ameise® products are available exclusively in the Jungheinrich PROFISHOP.