Jungheinrich

Buying TipsBasic quality

Products reduced to the essentials

For light and occasional use

Good quality

Strong performance

Robust products for everyday use

Premium quality

For the highest load demands

Designed for continuous use

- Steel, painted

- Suitable for 2,200 kg capacity

- For solid rubber steering castors

- Made from steel

- Suitable for 2,200 kg capacity

- With release lever on tiller handle

- Made from steel

- Suitable for 2,200 kg capacity

- With release lever on tiller handle

8 Working days

- Made from steel

- Suitable for 2,200 kg capacity

- With release lever on tiller handle

8 Working days

- Battery change module for the Jungheinrich AMW 22p weighing scale pallet truck

- Lasts approx. 35 hours

- Battery voltage of 12 V / 1.2 Ah

- Leistungsstarke 24 V / 36 Ah Lithium-Ionen-Batterie

- Wartungsfreier Einsatz und lange Lebensdauer

- Wechselbatterie für längere Einsatzzeiten und mehr Flexibilität

10 Working days

- Effective lateral support rollers for Jungheinrich AMX and AMX-E scissor lift pallet trucks

- For maximum lateral stability

- Easy truck movement (forwards/backwards)

10 Working days

- Leistungsstarke 48 V / 20 Ah Lithium-Ionen-Batterie

- Wartungsfreier Einsatz und lange Lebensdauer

- Wechselbatterie für mehr Flexibilität und längere Einsatzzeiten

10 Working days

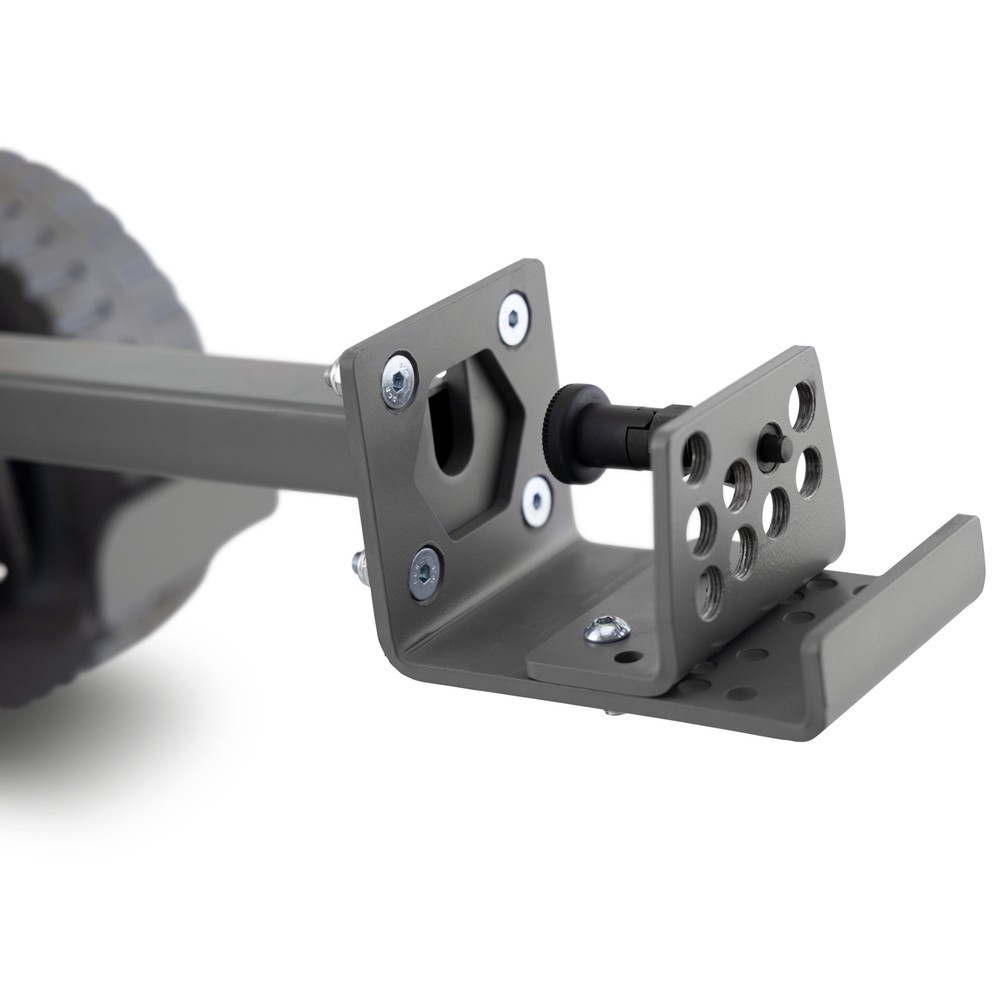

- Transport of trolleys with square profile on the lower edge

- For profile edges with depth of 5 to 60 mm

- Mechanical adjustment of the profile width in 5 mm increments

- Specially designed for transporting LKE trailers

- For shelf trolleys, X-frame trolleys, taxiliners, etc.

- Height of coupling arm infinitely adjustable from 135 to 285 mm

10 Working days

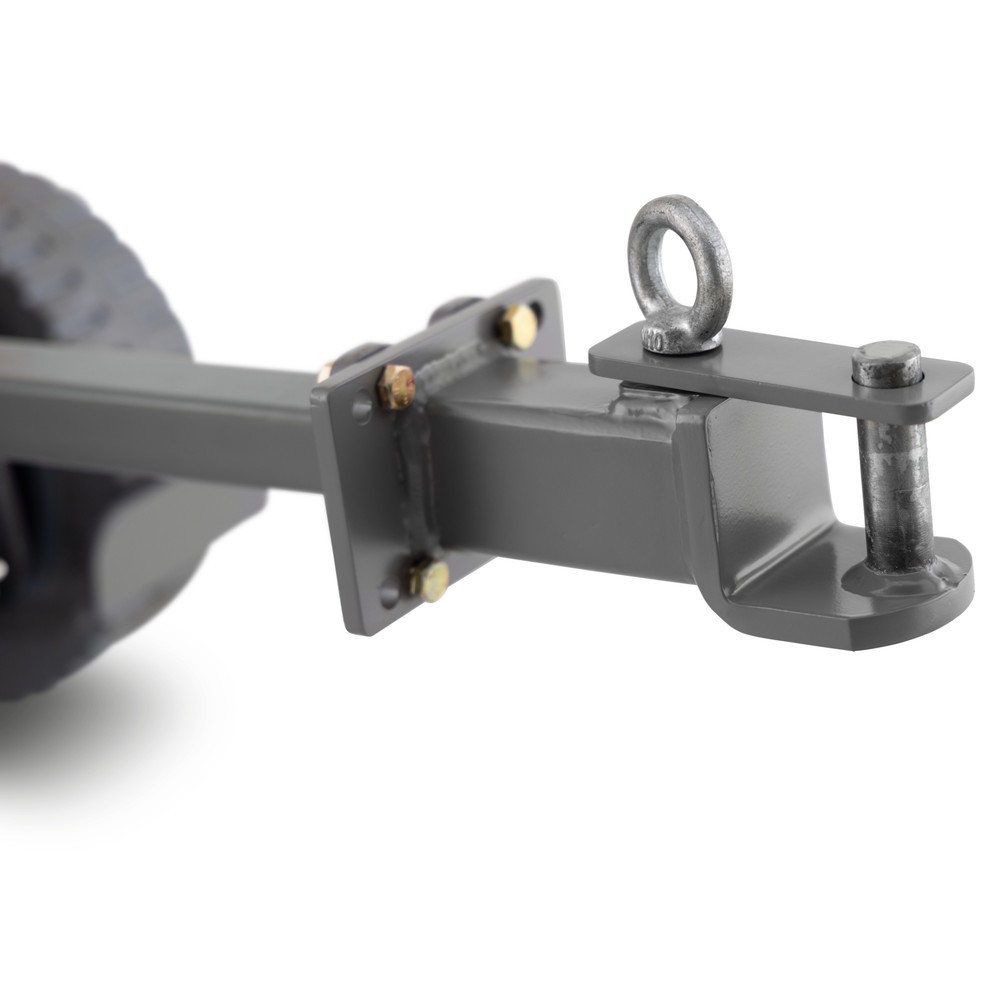

- Transport of trolleys with round towing eye

- Height of coupling arm infinitely adjustable from 150 to 250 mm

- Bolt secured by cotter pin

10 Working days

- Premium stainless steel pallet truck in professional design

- Fully corrosion and acid-resistant

- Sealed hydraulics prevent ingress of water

35 Working days

- Premium stainless steel pallet truck in professional design

- Fully corrosion and acid-resistant

- Sealed hydraulics prevent ingress of water

35 Working days

- Corrosion and acid-resistant chassis

- Closed fork tips to protect against dirt splashes

- Easy to clean

35 Working days

- Corrosion and acid-resistant chassis

- Closed fork tips to protect against dirt splashes

- Easy to clean

35 Working days

- Corrosion and acid-resistant chassis

- Closed fork tips to protect against dirt splashes

- Easy to clean

35 Working days

- Premium stainless steel pallet truck in professional design

- Fully corrosion and acid-resistant

- Sealed hydraulics prevent ingress of water

35 Working days

- Low entry height of just 51 mm

- Quick lift (up to 120 kg)

- Connections feature lifetime lubrication for maintenance-free use

65 Working days

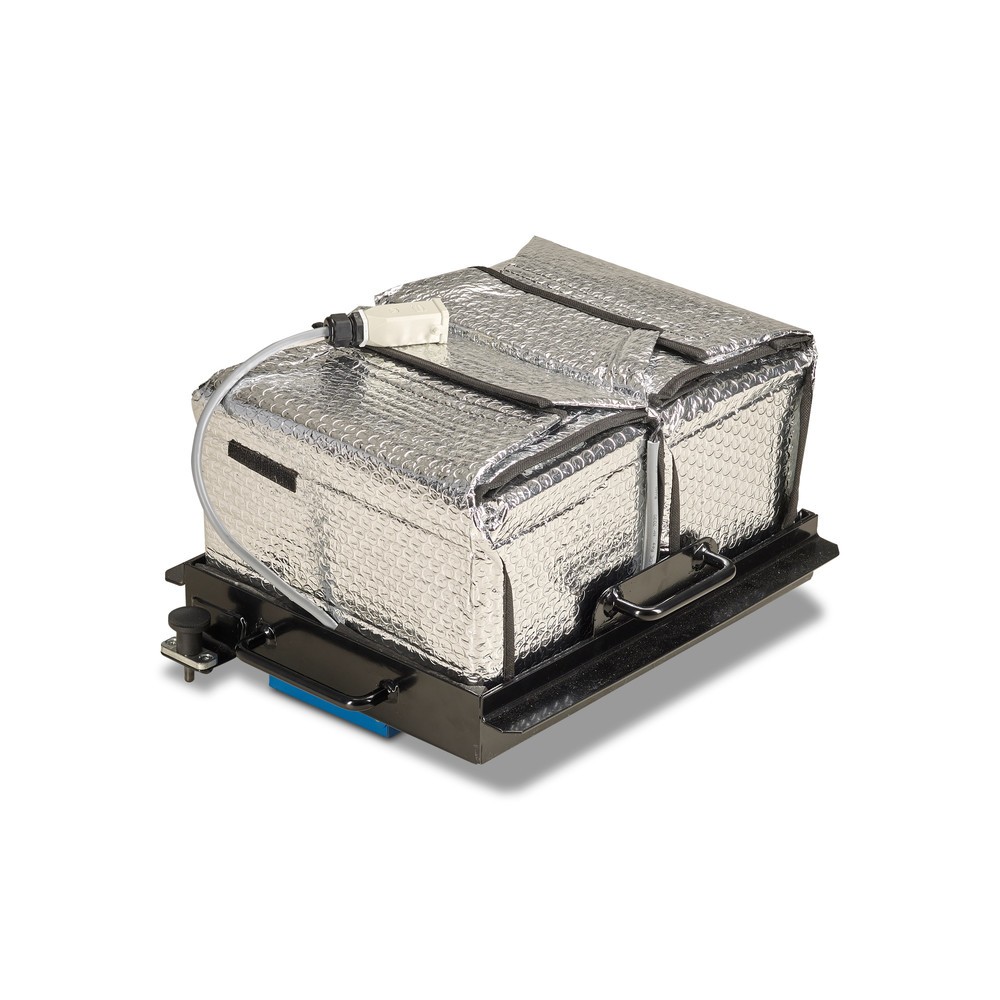

- Convenient battery water replenishment

- Optimum storage solution for battery water

- Water tank with 30 litre capacity

12 Working days

- Officially recognized adjustment document

- Confirms the weighing accuracy of the balance Complies

- with the standard EN DIN ISO 17025

20 Working days

- Thermal printer for the Jungheinrich AMW 22p weighing scale pallet truck

- Prints 24 characters per line

- Compatible with the displays of the AMW 22p

30 Working days

- Durable lithium-ion battery for the Jungheinrich mobile workstation

- Power: 12.8 V / 100 Ah

- Low weight (18 kg) for single-person use

25 Working days

- Made from steel

- Suitable for 1,000 kg capacity

- With release lever on tiller handle

35 Working days

- Made from stainless steel

- Suitable for capacities up to 2,000 kg

- For polyurethane steering castors

45 Working days

Jungheinrich – the reliable partner for your intralogistics

Today, Jungheinrich is one of the most renowned manufacturers of robust industrial trucks, versatile warehouse equipment and other high-quality products for intralogistics. Founded as a small workshop in Hamburg, the family business initially made a name for itself with import-export trade and was renamed a machine factory in 1953 by Dr Friedrich Jungheinrich. This laid the foundation for today's Jungheinrich AG.

In the years and decades that followed, the small family business from Hamburg became an internationally successful group of companies that is known primarily as a manufacturer of reliable and high-quality industrial trucks. While Jungheinrich initially produced robust hand pallet trucks, the company soon expanded its product range to include powerful electric pallet trucks and stacker trucks, distinguished by their resilience and flexibility in a wide variety of working environments. With the development of innovative solutions for warehouse technology and logistics, Jungheinrich adapted alongside the technical optimisation and automation of warehouse processes in industrial companies and ultimately became one of the world's leading intralogistics companies.

The focus has never been on quick success, but on consistent, sustainable growth. For this reason, all corporate decisions to this day are characterised by close, trusting relationships with employees and customers, while responsibility towards society and the environment plays a major role in Jungheinrich's self-image.

1. What are the distinguishing features of Jungheinrich products?

Industrial trucks from Jungheinrich are instantly recognisable by their uniform yellow design – now part of everyday life in many warehouses and production plants. For all product lines, the focus is on functionality: a clear, straightforward design in the unmistakable Jungheinrich yellow underlines the reliability and performance of all products. Today, the Jungheinrich brand is synonymous with:

- High technical quality

- Innovative further development of successful models

- Lasting performance

- High-quality, durable materials and workmanship

- Intuitive operability

- Compact design

- Versatile model variants

In addition to the high quality of its products, Jungheinrich owes its success above all to its strong customer orientation: when developing new solutions, the experience and needs of customers are considered from the outset. The global service network also makes it possible that a Jungheinrich employee is always at your side – regardless of whether you need expert advice in your company or support from Jungheinrich customer service.

2. Product selection in the Jungheinrich PROFISHOP

Are you looking for material handling and lifting equipment that can facilitate and optimise your warehouse processes? With innovative technology, functional designs and a resilient construction, Jungheinrich offers you high-performance lifting equipment in a diverse range of models:

3. Accessories for Jungheinrich products

With a range of pallet truck accessories available, you can optimally adapt Jungheinrich transport and lifting equipment to the work processes in your company. This includes additional and replacement rollers, braking, anti-static and noise reduction features, among others. Additional equipment and special functions are also available upon request.