Jungheinrich Electric stacker trucks

Buying TipsBasic quality

Products reduced to the essentials

For light and occasional use

Good quality

Strong performance

Robust products for everyday use

Premium quality

For the highest load demands

Designed for continuous use

- 1200 kg load capacity

- 4 lift heights available (2600, 2900, 3200, 3600 mm)

- Maintenance-free lithium-ion battery

10 Working days

- 1,200 kg load capacity

- Initial lift for increased ground clearance on loading ramps

- Maintenance-free lithium-ion battery

10 Working days

- 1,000 kg load capacity

- 4 different lift heights available (2,300, 2,500, 2,900 and 3,300 mm)

- Powerful, maintenance-free lithium-ion battery

21 Working days

- 1,000 kg load capacity

- 2 mast heights available (1,540 and 1,900 mm)

- Powerful, maintenance-free lithium-ion battery

44 Working days

- Premium quality – "Made in Germany"

- Powerful and maintenance-free three-phase AC drive motor

- Proportional hydraulics for precision lifting and lowering

60 Working days

- Premium quality "Made in Germany"

- 1,200 kg load capacity

- 3 different lift heights available (4,090, 4,300 and 4,700 mm)

60 Working days

- Premium quality "Made in Germany"

- 1,000 kg load capacity

- 6 different lift heights available (2,300, 2,500, 2,900, 3,200, 3,600 and 3,900 mm)

60 Working days

- Premium quality "Made in Germany"

- 1,200 kg load capacity

- 6 different lift heights available (2,300, 2,500, 2,900, 3,200, 3,600 and 3,900 mm)

60 Working days

- Premium quality – "Made in Germany"

- Powerful and maintenance-free three-phase AC drive motor

- Proportional hydraulics for precision lifting and lowering

60 Working days

- Premium quality "Made in Germany"

- Wide-track version for closed pallets and special load carriers

- Fork arms individually adjustable

60 Working days

- Premium quality "Made in Germany"

- 1,200 kg load capacity

- 9 different lift heights (2,300, 2,500, 2,700, 2,900, 3,200, 3,600, 3,900, 4,100 and 4,300 mm)

60 Working days

- Premium quality – "Made in Germany"

- Powerful and maintenance-free three-phase AC drive motor

- Proportional hydraulics for precision lifting and lowering

60 Working days

- Premium quality "Made in Germany"

- 1,000 kg load capacity

- 7 different lift heights available (2,300, 2,500, 2,700, 2,900, 3,200, 3,600 and 3,900 mm)

60 Working days

- Premium quality "Made in Germany"

- 1,000 kg load capacity

- 2 different lift heights available (4,090 and 4,300 mm)

60 Working days

- Premium quality – "Made in Germany"

- Powerful and maintenance-free three-phase AC drive motor

- Proportional hydraulics for precision lifting and lowering

60 Working days

- 1,300 kg load capacity

- 4 different lift heights available (2,300, 2,500, 2,900 and 3,300 mm)

- Powerful, maintenance-free 100 Ah lithium-ion battery

31 Working days

- Premium quality "Made in Germany"

- Double-deck function for simultaneous transport of 2 pallets

- 1,200 kg load capacity with mast lift and 1,600 kg with support arm lift

55 Working days

- Premium quality "Made in Germany"

- 1,000 kg load capacity

- 3 different lift heights available (1,200, 1,540 and 2,000 mm)

- Premium quality "Made in Germany"

- Support arm lift for flexible use on ramps and thresholds

- 1,200 kg load capacity

55 Working days

- Premium quality "Made in Germany"

- Support arm lift for flexible use on ramps and thresholds

- 1,000 kg load capacity

55 Working days

- Premium quality "Made in Germany"

- Double-deck function for simultaneous transport of 2 pallets

- 1,000 kg load capacity with mast lift and 1,400 kg with support arm lift

55 Working days

- Premium quality "Made in Germany"

- Support arm lift for flexible use on ramps and thresholds

- 1,200 kg load capacity

55 Working days

- Premium quality "Made in Germany"

- Double-deck function for simultaneous transport of 2 pallets

- 1,200 kg load capacity with mast lift and 1,600 kg with support arm lift

55 Working days

- Premium quality "Made in Germany"

- Double-deck function for simultaneous transport of 2 pallets

- 1,200 kg load capacity with mast lift and 1,600 kg with support arm lift

55 Working days

Jungheinrich electric pallet stacker trucks for transporting loads vertically

With an electric pallet stacker from Jungheinrich, you can not only move palletised goods and other goods that can be carried from underneath quickly and safely from A to B, but also lift them to great heights. Find out about the differences between the various Jungheinrich electric pallet stacker models and what you need to consider when selecting the right truck for your business in our buyer's guide.

1. What is a Jungheinrich electric pallet stacker truck and how is it different from a forklift?

All Jungheinrich electric pallet stackers with electric drive are equipped with a mast. With this, not only is the ground-level transport of goods possible, but also the vertical transport of wire mesh boxes, pallets and other goods up to heights of 4800mm. For this reason, these industrial trucks are also referred to as electric high-lift trucks. With them, you can handle loads ergonomically and safely – and without the use of muscle power: regardless of the model, the lifting process for Jungheinrich electric stackers is always performed automatically.

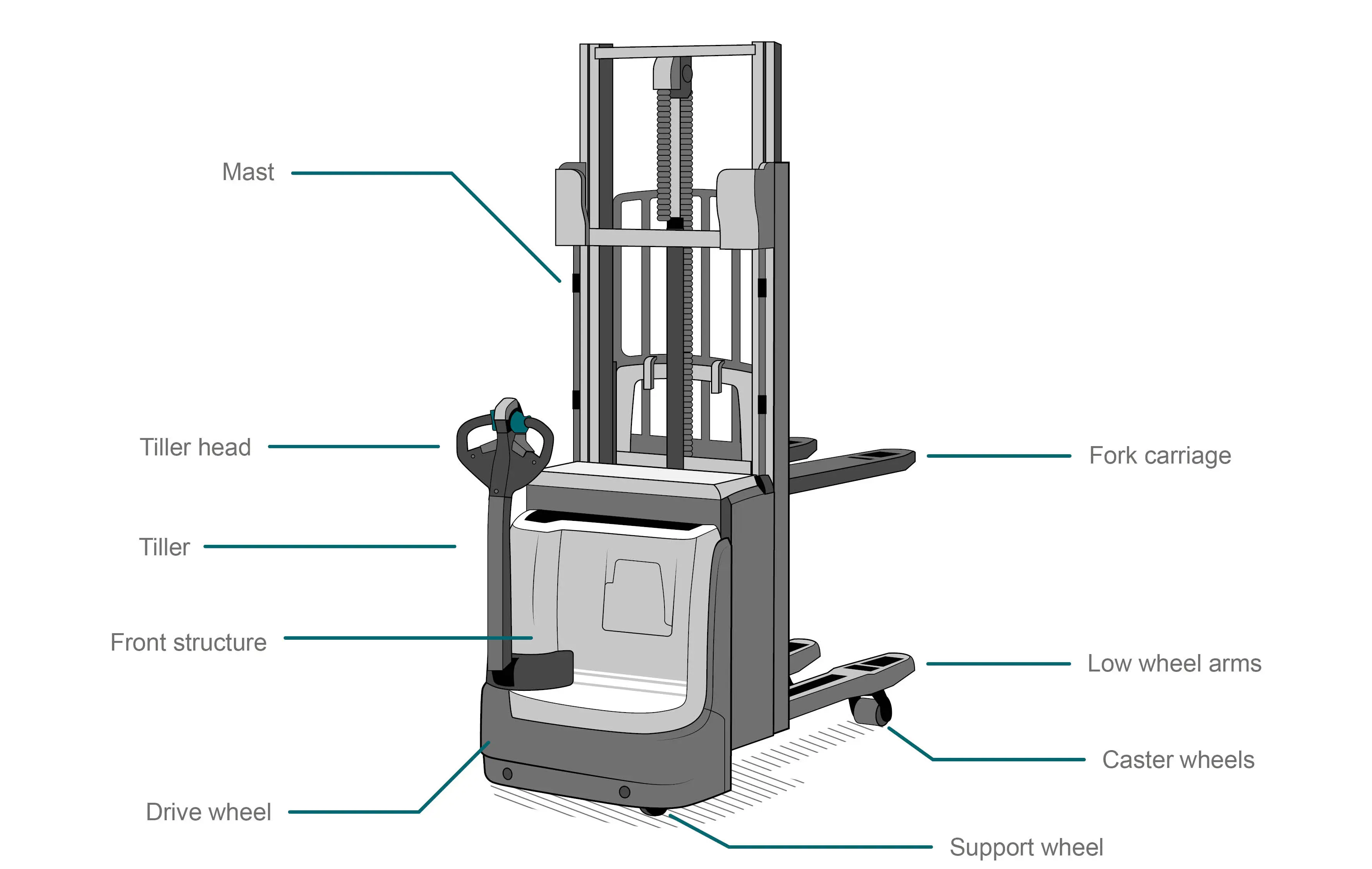

Depending on the required lifting height and rated capacity, we offer models with different mast types. Our graphic shows an example of a model with a double telescopic mast:

Unlike forklifts, Jungheinrich e-stackers do not require a counterweight for safe lifting. Their load centre is located within the fork structure, so they operate safely even when loaded. This makes them very manoeuvrable in operation and also allows them to be used in both wide and narrow warehouse aisles. All functions of Jungheinrich electric pallet stackers are controlled via the low-mounted tiller or the ergonomic control panel on the tiller head. This is why these versatile and powerful models are often referred to as Jungheinrich electric pedestrian stacker trucks.

2. How to find the right Jungheinrich electric stacker truck

Jungheinrich electric pallet stackers are available in different model variants in our online store. Among other things, the trucks differ in their rated capacity, lifting height and general performance. The requirements that the truck should meet are largely determined by the working and operating environment in which they will be used. By compiling a detailed requirements profile, you can quickly find a model that fits your specific operation:

- How many hours will the Jungheinrich electric pallet stacker truck be used per day?

- What transport distances must be covered?

- At what heights must the goods be stored?

- What are the ceiling heights in your warehouse or sales rooms?

- Will the Jungheinrich battery-powered pedestrian stacker be carried or transported on a lorry?

- Do fragile goods need to be transported?

- Are the travel routes free of barriers, such as inclines or ramps, or do such obstacles have to be driven over?

In the following, we go into more detail on the questions from the requirements profile so that you can quickly find a suitable Jungheinrich e-truck for your operation.

Consider where the Jungheinrich electric pallet stacker truck will be used

The working environment and the intended use are important criteria when it comes to selecting the right stacker truck. The truck you choose should always match these criteria, so that it can perform as required:

| Area of application | Suitable electric pallet stacker from Jungheinrich |

|---|---|

| Indoor and/or outdoor |

|

| In combination with a truck/lorry |

|

| Ceiling height or lowest clearance |

|

| Length of the transport routes |

|

| Environments with ramps or inclines |

|

The Jungheinrich electric pallet stacker trucks from our online store are suitable for use in dry indoor areas (without condensation) and occasional use in dry outdoor areas. However, for stacking and retrieving goods in demanding work environments, we offer various model variants as part of our special construction service.

On request, we can supply Jungheinrich electric pedestrian stackers made of stainless steel, for example, which are suitable for clean rooms, hygiene-sensitive areas or corrosive working environments. We also offer models with cold storage equipment on request: you can use these trucks in very cold or damp environments, e.g., in deep-freeze cold storage rooms or greenhouses.

Determining the type of drive for your Jungheinrich electric pallet stacker

The versatile Jungheinrich e-stacker trucks are available with two different drive variations:

- Semi-electric: These models have a lift motor that lifts and lowers loads automatically. Semi-electric pallet stackers are moved manually by means of the tiller. Ergonomically arranged guide handles facilitate pushing and manoeuvring when stacking and retrieving.

- Fully electric: These pedestrian stackers from Jungheinrich have two motors and are therefore a particularly convenient solution for storage and transport tasks. The drive motor controls the forward and reverse movements. Once at the destination, the lift motor raises or lowers the fork carriage together with the load. The operator conveniently controls both functions via the controls on the tiller head.

Which drive variant is right for you depends on how often you use the lift function in your day-to-day operations and what lifting heights you need to achieve with the truck. If stacking tasks only occur infrequently or occasionally in the internal transport of goods, a semi-electric stacker can be a cost-effective solution. For greater lifting heights, fully electric pallet stackers from Jungheinrich are the more suitable option – especially for regular use.

Regardless of the drive type, we also carry models with proportional hydraulics: The function enables precise stroke pulse control so that even delicate loads such as glassware or sensitive electronic components can be sensitively lifted, lowered and placed on the shelf or floor.

Choose a model with sufficient vertical lift capability

The mast moves the load carrier and the load vertically. Depending on how high your storage racks are or at what height loads have to be stored and retrieved in your operation, select a Jungheinrich electric pallet stacker with the appropriate vertical lift capability. Other parameters are important in the selection as well. These determine where you can use the device for stacking and retrieval:

| Parameter | Significance |

|---|---|

| Lifting mast, headroom |

The overall height is the maximum height of the Jungheinrich electric truck, measured from the ground. It can change depending on whether the mast is extended or retracted. |

| Maximum lifting height |

This term refers to the greatest possible distance from the ground to the highest position of the load handling attachment (upper edge of the fork) in the lifted state. |

| Free lift |

This refers to the lifting height up to which the load handling attachment can move upwards without changing the overall height of the mast. The free lift function is ideal when stacking is required at low ceiling heights, e.g., in containers, enclosed rail freight cars or basements. |

The dimensional data for all three parameters are listed in the technical details for each Jungheinrich battery-powered pedestrian stacker truck.

Mast types: features and advantages of the different models

Jungheinrich electric high-lift trucks are available with four different types of masts. The operating principle is the same for all versions: the fork carriage and the load is moved vertically within the mast by a motor. On some models, the mast can be further extended two or even three times. In this way, much higher storage spaces are achieved without restricting mobility in low working areas.

| Type of Mast | Construction | Advantages | Disadvantages |

|---|---|---|---|

Simplex mast = single lift mast

|

|

|

|

Mono mast = single column mast

|

|

|

|

Duplex mast = two-part telescopic mast (with or without additional stroke) (free stroke)

|

|

|

|

Triplex = three-part telescopic mast with additional stroke (free stroke)

|

|

|

|

Please note: To ensure sufficient stability, you should also always pay attention to the ground. Uneven or damaged floors can affect the balance when stacking and unstacking palletised goods - regardless of the mast height installed.

Buy Jungheinrich electric pallet stacker trucks with sufficient lifting capacity

The weight-specific limit with which a Jungheinrich electric pallet stacker can be loaded is referred to as the load capacity or rated capacity. This must not be exceeded in order not to overload the load-bearing parts of the industrial truck and to ensure safer handling of the truck. The following applies: the heavier the Jungheinrich e-truck, the higher its load capacity (taking into account the fork dimensions and quality of the steel used as well). The load capacity diagram, which can be viewed on every Jungheinrich electric pallet stacker, also shows how the rated load capacity depends on the lift height and load centre in each case.

The residual load capacity must also always be considered: if, for example, attachments are used on the Jungheinrich electric pallet truck, the general load capacity is reduced because the load centre of gravity also changes. You can find more information on this in our guide "Carrying capacity for industrial trucks - Dimensioning loads correctly".

Fork lengths and features: what goods do you want to transport?

Basically, all Jungheinrich electric pallet stackers with electric drive are designed for transporting loaded Euro pallets. However, depending on the fork dimensions and load capacity, you can also use the industrial trucks to move storage bins, ISO containers and skeleton containers or even long goods and pallets in special sizes.

The standard fork length of Jungheinrich electric pallet stackers is 1150mm. This enables uncomplicated lifting of Euro pallets and mesh pallets without a great deal of manoeuvring. The standard size fork carriage width varies between 540 and 570mm depending on the model.

In contrast, Jungheinrich pedestrian stackers in a wide-gauge design are suitable for picking up special pallets. On request, we also offer special design variants, e.g., Jungheinrich electric pallet stackers with special fork lengths.

Influence on performance, service life and charging time: battery size and type for your Jungheinrich e-truck

The Jungheinrich electric pallet stackers in our range are equipped as standard with one of the following three rechargeable battery types:

- Lead gel batteries or lead acid battery: The capacity of the powerful traction batteries enables reliable work in the warehouse. The display instrument on the chassis allows you to keep an eye on the battery charge level and the number of operating hours at all times. When the capacity of the lead-acid battery is exhausted, you can conveniently charge it with the integrated charger at a 230-volt socket.

- Lithium-ion battery: As soon as you need more performance, we recommend the low-consumption Jungheinrich lithium-ion trucks. The batteries have a long service life, offer high energy efficiency in a compact design and can be easily recharged. The integrated charger recharges the lithium-ion battery regardless of location and in the shortest possible time.

The direct performance comparison of the three battery types outlined below should make things easier when choosing the appropriate model:

| Features | Lithium-ion battery | Lead-acid battery | Lead-gel battery |

|---|---|---|---|

| Life expectancy |

~ 3,000 charging cycles |

~ 1,200 charging cycles |

~ 900 charging cycles |

| Charging time |

1.5-3 hours |

At least 6.5 hours |

At least 6.5 hours |

| Maintenance |

None |

Refill demineralised water 1x a week |

None |

| Intermediate charging |

Possible at any time |

Only possible to a limited extent |

Not possible |

| Battery change during multi-shift operation |

Avoidable by intermediate charging |

Required |

Not recommended |

| Advantages |

|

|

|

| Disadvantages |

|

· Infrastructure for separate battery charging stations necessary |

|

| Application |

|

|

|

You can read about how the various batteries are constructed and supply industrial trucks with energy in our guide "Battery technology for electric pallet stacker trucks and industrial trucks".

Tyres for your Jungheinrich electric pallet stacker truck

All Jungheinrich electric pallet stackers have a 4-point chassis to ensure optimum stability and driving safety when stacking and retrieving loads. The chassis consists of a drive wheel, a support wheel and two or four fork rollers. The diameter of these is significantly smaller than that of counterbalanced trucks, as they are generally designed for use on level flooring. The fork rollers can be selected as single or tandem fork rollers:

| Caster design for Jungheinrich electric pallet stackers | Features and suitability |

|---|---|

| Single fork rollers |

These wheels are preferred for use on flat floors and allow easier manoeuvring than with tandem rollers. However, wear on these rollers is higher than with tandem rollers. |

| Tandem fork rollers |

Tandem rollers are particularly suitable for uneven floors and overcoming speed bumps. The weight of the load is distributed over four rollers, which reduces the contact pressure and thus the wear per roller. As a result, Jungheinrich electric pallet stacker trucks run more smoothly and stably, especially on uneven surfaces. |

While floor condition is one of the most important selection criteria for Jungheinrich electric pallet truck tyres, there are also some other parameters to consider:

- Noise emission

- Starting and rolling resistance

- Load capacity

- Impact load (when driving over bumps, potholes or thresholds)

- Hygiene requirements

- Environmental influences such as moisture or chemicals

- Climatic conditions

- Electrical conductivity requirements

When you buy a Jungheinrich electric pallet stacker, the tyres should be as suitable as possible for the respective area of application. The material properties of the rollers differ fundamentally in some cases:

| Properties or suitability / material | Polyurethane (PU) | Thermoplastic Polyurethane (TPU) | Nylon | Solid rubber |

|---|---|---|---|---|

| Smooth surfaces | × | × | × | × |

| Moist oily surfaces | × | × | × | × |

| Sensitive surfaces | × | × | × | × |

| Chemically resistant | × | × | × | × |

| Uneven surfaces | × | × | × | × |

| Low-noise | × | × | × | × |

| Abrasion resistant | × | × | × | × |

| Heavy duty | × | × | × | × |

| Wear resistant | × | × | × | × |

| Available for roller type | For drive wheels, support wheels and load rollers |

Only for drive wheels |

For drive wheels, support wheels and load rollers |

Only for drive wheel |

For PU wheels we also offer the following special features upon request:

- For environments where electrical conductivity must be considered, we carry anti-static PU drive wheels. These dissipate an electrostatic charge into the ground and thus prevent punctures.

- For particularly smooth or slippery surfaces, you can also choose PU wheels sanded with quartz sand. These special drive wheels enable improved ground contact (traction) due to the coating.

Jungheinrich electric pallet stackers in pedestrian or rider operation

The Jungheinrich e-trucks in our online store are available exclusively with pedestrian operation. In this operating mode, all steering and operating functions are performed by an operator who accompanies the truck. For optimum operating safety, the industrial trucks are equipped with a long, low-set tiller. This ensures a sufficient safety distance between the vehicle frame and the operator. Swiveling the tiller moves the drive wheel in the desired direction of travel. You can conveniently operate the machine using the controls mounted on both sides of the tiller head. These are located on each model to be suitable for both right-handed and left-handed operators. Jungheinrich electric pallet stackers with pedestrian operation can handle short and medium transport distances.

On request via our contact form you can also order these operating variants from us:

- Ride-on operation: With these Jungheinrich electric high-lift trucks, all steering and operating functions are performed by an operator standing or sitting in a protected operator's platform. These trucks are particularly suitable for medium and longer transport distances.

- Combined pedestrian or rider operation: All steering and operating functions are performed either by an operator walking alongside the equipment or riding on it. A folding or permanently installed driver's platform can serve as a workstation in pedestrian operation.

Please note: As Jungheinrich electric pallet stackers with a stand-on platform reach a speed of more than 6km/h, a special forklift driver's licence is required for their operation.

3. The types of Jungheinrich electric pallet stackers available in our range

In our online store, you will find an electric pallet stacker truck from the Jungheinrich brand for every application and requirement.

Jungheinrich electric pallet stackers with additional support arm lift

Our Jungheinrich stacker trucks with an additional support arm lift are ideal when you need to:

- Drive on uneven floors more frequently

- Negotiate speed bumps such as drive-over plates

- Cope with ramp crossings and loading bridges

By raising the support arms, you can ensure that the Jungheinrich e-truck gains more ground clearance and that safe and stable travel is guaranteed even when driving over uneven surfaces or thresholds. Depending on the type of support arm, slopes of up to 16% can be mastered. For comparison: without an additional support arm lift, only inclines of 5% can be overcome.

Electric wide-thread pallet stacker trucks from Jungheinrich

Some electric pallet stackers in the Jungheinrich Performance Series are available as wide-thread versions. In addition to Euro pallets, these models can also pick up closed load carriers and UK pallets without any problems. Transverse pallet pick-up is also possible with this type of truck. This is carried out by extending the support arms at the sides and lowering the fork to the floor to lift the load unit from below.

These trucks are designed with specific support arm spacing: this limits the maximum length or width of the load being lifted in each case and should be matched to the goods being transported. If you need to transport goods in deviating sizes, wide-thread variants with other dimensions are optionally available. In models with an ISO fork carriage (e.g. the Jungheinrich EMC B10 electric pallet stackers – wide-thread version), the fork carriage can also be adjusted so that pallets in special sizes can be transported.

Our wide-thread electric pallet stackers are supplied with a standard design that allows for the transport of pallets up to approx. 900mm in width. Optionally, the distance between the support arms can be extended by further modifications up to a maximum of 1270mm.

The advantages of Jungheinrich electric pallet stackers in a wide-thread design:

- Pick-up of closed goods and special pallets

- Transverse pick-up of (Euro) pallets

- Forks can be lowered to the floor

- Different support arm distances optionally available

- Models with an adjustable ISO fork carriage allow the mounting of various attachments, such as crane hooks and drum turners.

Two-stage mast electric pallet stackers from Jungheinrich

Our electric two-stage mast stackers from Jungheinrich are particularly practical, as the trucks combine the performance features of Jungheinrich pallet trucks and electric stackers in one powerful device. The dual mast models are designed to move up to two pallets at a time.

This is made possible by the additional support arm, which provides a second lifting function for picking up another pallet. The support arm and mast work independently of each other. The additional arm allows goods to be picked up and transported on top of each other without putting any pressure on the goods positioned on the lower pallet.

This is how the additional lift works on Jungheinrich electric pallet stackers with two-stage mast function:

- The first pallet is picked up with the forks.

- The pallet is lifted using the normal mast lift.

- The support arm is activated via the operating element on the tiller head.

- The support arms drive under the second pallet and pick it up.

Electric pallet stackers from Jungheinrich with special equipment

Our Jungheinrich electric pallet stackers are already available in many different variants and equipment options. On request, however, it is possible at Jungheinrich PROFISHOP to have a model equipped with additional individual functions. These include, for example, indicator displays, organiser functions or special drive wheels. Depending on the model, the following equipment is also possible as part of a special design request:

- Different lifting masts

- Different battery types and sizes as well as chargers

- Individual access systems

- Refrigeration or deep-freeze equipment

- Ramp comfort

- Proportional hydraulics for particularly sensitive loads

- Aquamatics for simplified maintenance of lead-acid batteries

- Special fork lengths and fork widths

- Stainless steel design

4. FAQ for Jungheinrich electric pallet stackers

The use of Jungheinrich electric high lift trucks in warehouses, dispatch or sales areas is advantageous for many reasons:

- Jungheinrich electric pallet stacker trucks are offered as entry-level units, models for medium-intensity operations or high-performance units. This means that the requirements profile and investment costs can be brought into a worthwhile relationship for any budget – even for small companies.

- Many models do not require the operated to have a forklift license.

- Electric drive increases productivity and efficiency.

- Your employees benefit from electric motor assistance, which promotes ergonomic work.

- The high level of user-friendliness enables simple and intuitive operation of the equipment.

- Jungheinrich e-stackers are versatile and are used for transport, storage, retrieval and order picking.

- A suitable truck is available for every application scenario, which can be further tailored to your personal needs with individual options if required.

Not necessarily. With a pedestrian electric truck from Jungheinrich, you do not need a forklift driving licence, but only company-specific instruction on all relevant safety regulations, such as possible accident risks, the function of the truck and its attachments and stability, before the truck is put into operation for the first time. However, if the Jungheinrich pedestrian stacker is a combined pedestrian/ride-on model or purely a ride-on model, a forklift licence is required, as the machine can achieve speeds of more than 6km/h.

Jungheinrich electric pedestrian stackers should only be used outdoors if the trucks are designed for this purpose. The outdoor areas should be dry, and the device should not be subject to poor weather conditions. For this reason, most Jungheinrich electric pallet stacker trucks must not be used in cold stores or freezers or for interchangeable applications with condensation, as they can be damaged by the moisture. Jungheinrich electric pallet trucks are also not suitable for environments with high dust content or for use on oily and very wet surfaces: robust electric pallet stackers with combustion engines are the better choice here.