Table of contents

Rolling resistance is a parameter that counteracts the rotational movement of the wheels on lift trucks or stacker trucks. A high rolling resistance leads to higher energy consumption as well as a higher degree of effort when moving manual transport equipment.

Resistance, also known as rolling friction, is not a constant. It is highly dependent on the type of tyre and its rubber compound, the tyre dimensions, as well as variable factors such as tyre pressure or the floor surface. Unlike starting resistance, which refers exclusively to the amount of force required to start a vehicle, the rolling resistance of tyres is the permanent force generated when a wheel rolls and is directed in the opposite direction to the movement. With the help of rolling resistance coefficient values and formulas, this guide aims to show you how to calculate and optimise these resistance forces.

Rolling resistance formulas: How to calculate rolling resistance of tyres

You can easily calculate the rolling resistance of tyres by using the following steps.

- Calculating rolling resistance on a level surface

Rolling resistance (FR, also called rolling friction coefficient) can be calculated using the following formulas:

FR = CR x FN

The resistance is thus calculated from the rolling resistance coefficient (CR) and the normal force (FN). The normal force in this formula refers to the weight force of the transport vehicle in kilograms (kg) on a horizontal road without an incline or decline and without aerodynamic effects such as lifting or pressure on the tyres. - Calculating the rolling resistance coefficient

The rolling resistance coefficient depends on the material properties of the tyre and the road surface, as well as the dimensions of the tyre (R=radius) and the distance travelled in metres (d). The value is necessary for calculating the rolling resistance and can be determined with formula:

CR=d/R

The distance here is the distance of the normal force (FN) to the centre of the wheel and results from deformations during rolling. - Calculation of the rolling resistance with known rolling resistance coefficient

The rolling friction coefficient depends significantly on the combination of surface and tyre material and does not have to be calculated additionally if tables for friction values of different material pairings are available. Here you can simply look up the value and insert it into the calculation formula.

- Calculating rolling resistance for forklift tyres

If you want to calculate the rolling resistance for forklifts, in addition to the weight force of the vehicle, the mass of the load (FZul) and the gravitational acceleration g (g = 9,81 m/s2) must also be taken into account. For a level surface, use this formula for calculation:

FR = (FN + FZul) ∙ g ∙ CR ∙ cos(α)

If the industrial truck is driving on an incline, the ramp angle α also influences the rolling resistance of the tyres:

FIncline = (FN + FZul) ∙ g ∙ sin(α)

Factors that influence the rolling resistance of tyres

The following factors must be considered when determining rolling resistance. Some are directly dependent on the tyre, others can be changed independently of the tyre.

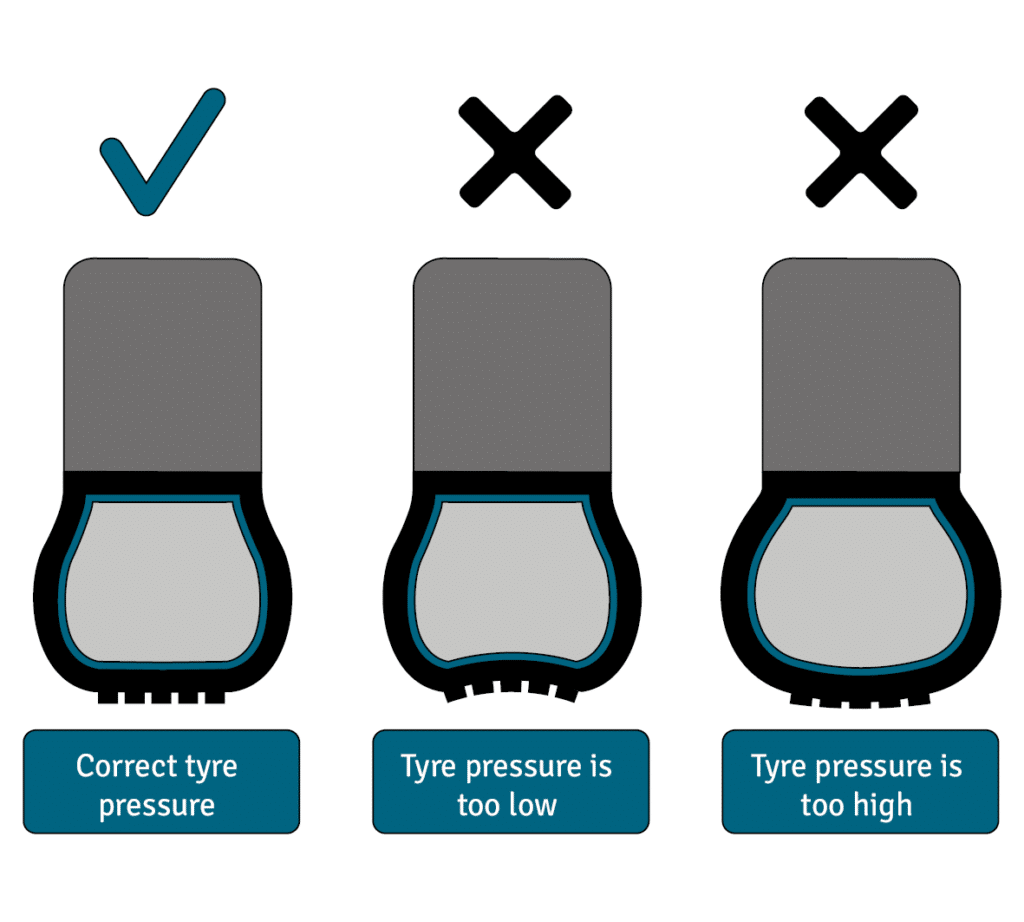

Tyre pressure

The lower the tyre pressure, the higher the resistance that must be overcome when starting. Therefore, all means of transport – from forklift trucks to sack trucks – should always have optimal tyre pressure and should be checked once a month. The optimum tyre pressure for pneumatic tyres is 9 bar. Under no circumstances, however, should the tyres be overinflated to the point of posing a safety hazard. Before replacing tyres, first check whether incorrect tyre pressure is responsible for high rolling resistance.

What material the tyre is made of

When it comes to achieving the lowest possible rolling resistance, here’s a key principle: The harder the tyre’s surface material, the easier it rolls. However, it’s important to note that extremely low rolling resistance can negatively impact driving and braking performance. That’s why it’s crucial to match both tyre material and surface type to ensure the safe operation of forklifts, transport equipment, and similar vehicles:

- For slippery surfaces like tiles or linoleum, softer air-filled tyres are the best choice. These provide better grip on smooth surfaces while maintaining good rolling resistance.

- When dealing with hard surfaces such as asphalt or rubber flooring, it’s best to use polyurethane or rubber tyres. The nearly maintenance-free PU tires offer relatively low rolling resistance and good shock absorption, even on uneven and challenging terrain.

- To achieve the lowest rolling resistance on hard floors, polyamide (nylon) or steel tyres are your best bet. These materials are ideal for hard surfaces in hygiene-sensitive or other demanding environments due to their resistance to grease, alkalis, and acids.

Tyre design and dimensions

Modern fuel-saving or low rolling resistant tyres are characterised by a resistance-optimised construction that reduces the deformation of the tyre while driving. This deformation, along with the choice of material, is largely responsible for the rolling resistance.

As a general rule, wide and flat wheels have a higher rolling resistance than taller, narrow ones. However, this principle also depends on the surface. For example, vehicles with narrow tyres require significant effort to move on soft surfaces like sand. In such cases, wider tyres are actually better suited to minimise rolling resistance.

Age of the tyre

It is more difficult to move cars, trucks or forklifts with older and worn tyres than with new ones. However, even new tyres may temporarily have more resistance until they are broken in.

FAQs about the rolling resistance of tyres

Rolling resistance is a force that works against the rotational movement of wheels on vehicles like cars, pallet trucks or forklifts. When driving or using transport equipment, trucks, and industrial vehicles, it’s important to keep the rolling resistance as low as possible. High resistance leads to increased fuel consumption and/or requires more effort when moving manual transport equipment.

Unlike starting resistance, which only refers to the force needed when starting to move forward, rolling resistance is the constant force that is generated as a wheel rolls and opposes its motion.

The higher the rolling resistance of tyres, the more energy is needed to move the vehicle forward. For transport vehicles covering about 50,000 kilometres (about 31,000 miles) annually, using tyres optimised for low rolling resistance can save several hundred euros per year. Even for manual transport equipment, it’s advisable to aim for low rolling resistance as this makes transportation quicker, easier, and more ergonomic – which is better for both people and machines.

Image source:

© gettyimages.de – RicardoImagen