Table of contents

In some industries, particularly strict hygiene requirements are placed on the workplace. Industries such as medical research laboratories, biotechnology, aerospace technology or semiconductor manufacturing. To not jeopardize the work being done, these workspaces must be kept meticulously clean. This includes minimising even minuscule airborne particles. A room or workspace that meets these conditions is known as a ‘cleanroom’.

To achieve an internationally comparable standard, strict requirements and classifications apply to the operation of a cleanroom. They stipulate, among other things, the acceptable concentration of particles in the air, measures for air filtration and purification, cleanroom technology and equipment, transport equipment, work materials and machines, and work uniforms.

What standards apply to your company depends on the respective industry and the purpose of the cleanroom. Compliance with the relevant requirements is confirmed by an independent testing body, by means of certification.

What is a cleanroom and what is one used for?

A cleanroom is a workplace where the concentration of airborne particles and other contaminants is kept as low as possible, making the space far cleaner than the outside world. This means that highly sensitive manufacturing techniques or research experiments can take place under the necessary hygienic (even sterile) conditions.

Airborne particles are suspended particles (aerosols) of various compositions. The term is used for both solids and liquids and includes smoke, ash, pollen and spores, bacteria, viruses, and artificially generated nanoparticles.

Cleanrooms are often necessary because standard air is always polluted to a certain extent with dust, exhaust fumes, pollen or similar microparticles. While contamination levels might not be high enough to adversely affect day-to-day operations, the particles can detrimentally hurt standards in the production of food, computer chips or medicines. For this reason, using cleanroom technology is mandatory for the following industries and processes:

- Food production and processing

- Manufacture of semiconductor and computer technology

- Aerospace engineering

- Laboratory tests

- medical, biological and chemical research projects

- Optics and laser technology

- Manufacture of pharmaceutical products

Only in a cleanroom can the risk of contamination or damage by aerosols be kept low enough that the technical and hygienic requirements for reliable and safe production can be met.

How does a cleanroom work?

A cleanroom does not technically have to be a traditional ‘room’, so to speak. Parts of a building can be segregated off or ‘cleanroom tents’ can be established as temporary and more permanent cleanroom solutions by means of appropriate isolation from the external environment.

For this purpose, the cleanroom is designed in such a way that it forms a closed unit in which the particle concentration can be precisely measured and monitored. Meanwhile, other parameters such as humidity, air pressure, and temperature can be controlled so that desired conditions are maintained.

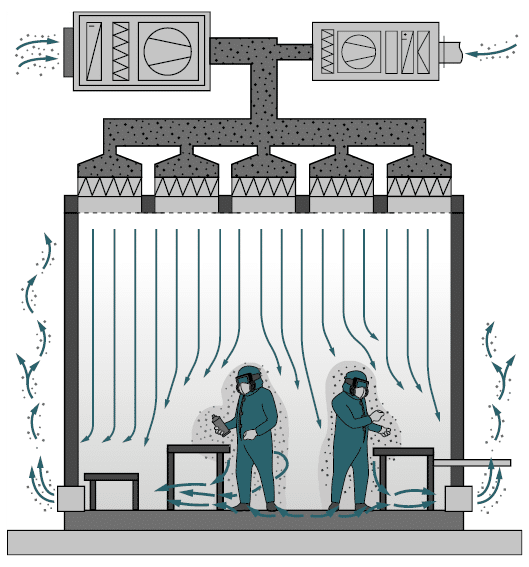

This is made possible via the appropriate cleanroom technology. High-performance ventilation and air-conditioning systems ensure that air is continually circulated and – in accordance with the required cleanroom classification – cleaned of particles that are produced during the work process. To facilitate this process, an airflow is created in which the particles move out of the room (positive pressure ventilation).

In some cases, negative pressure is used to suck out the airborne particles. However, this is only necessary for special safety requirements, e.g. when working with hazardous chemical substances or pathogens.

Pressure cascades to prevent germs in the cleanroom

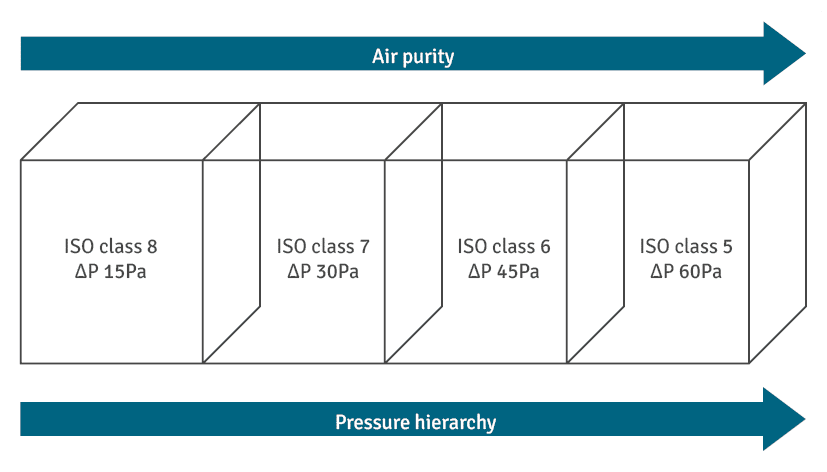

To remove contamination from the cleanroom as efficiently as possible, and to prevent the ingress of contaminating suspended particles from the outside, pressure cascades are used in many areas of application.

These physical measures gradually differentiate cleanroom classifications: The higher the pressure in the room, the greater the purity of the room air. The lowest cleanroom class (ISO 1) offers the highest pressure and ensures the greatest possible purity.

Pressure cascades are commonly used alongside airlock doors and combined with targeted techniques to control airflows. They prevent contaminated air currents from entering cleanrooms. This results in an overpressure cascade from pure to impure, which means that if an airlock door is opened, unwanted particles from a room with a lower cleanroom grade cannot enter because of the higher room pressure.

The ventilation technology of a cleanroom is primarily used to eliminate the particles that are produced during work. However, a much greater contamination risk often comes from employees, transport equipment and work materials that enter the cleanroom from the outside. A cleanroom airlock is needed to eliminate such contamination.

The cleanroom airlocks remove all particle residues from employees, as well as work equipment and materials, with the help of a strong airflow. Special dirt control mats with antibacterial adhesive ensure that even shoe soles and objects that come into contact with the ground are freed from dirt. Depending on the work area, a contamination suit or sterile clothing may also be needed.

Airflows and their importance in cleanrooms

People and objects inside a cleanroom still continuously emit aerosols and suspended solids that pollute the air. Depending on cleanroom grades, different requirements are applied to the ventilation technology: It can sometimes be sufficient to reduce the particle concentration in the room and mix the air volume. Large-scale air replacement may also be necessary to ensure that the environment is as particle-free as possible.

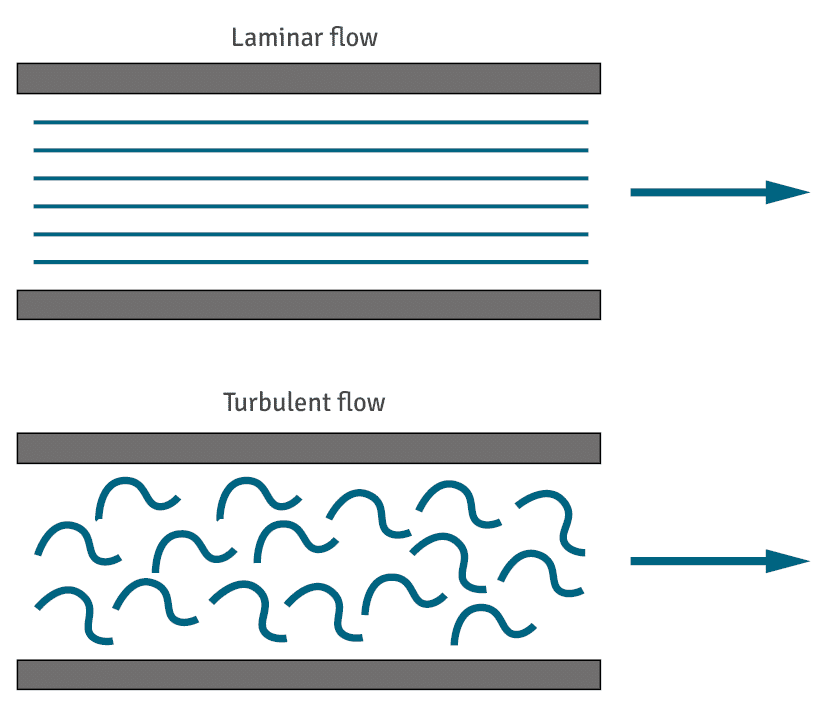

Air currents to prevent contamination are of particular importance in cleanrooms and can be either turbulent or laminar. A laminar flow is orderly and uniform, it is not restricted or diverted by obstacles such as objects or people and can propagate at a steady speed.

In theory, laminar air currents can keep the air particularly clean of particles. However, in practice, there are often obstacles. When the laminar flow hits people or objects, turbulence occurs and the suspended particles swirl around. Turbulent air currents increase the risk of contamination. With laminar airflows, contamination with suspended solids is up to ten times lower than when turbulent air currents prevail in a room.

What are the standards for cleanroom classification?

The tolerance for airborne particles and/or germs differs greatly between industries and applications, thus different cleanroom standards are required. For this reason, we have cleanroom grades based on cleaning and cleanliness levels.

The criteria for classification vary depending on the industry. For example, the particle concentration in the air is used for cleanroom grades in the semiconductor or aerospace industry. However, in the food industry, the number of microorganisms is also measured. For medicine and pharmacy, the germ count is the most important variable. To achieve uniform criteria both nationally and internationally, cleanroom classification is regulated to various standards:

- BS EN ISO 14644: “Cleanrooms and associated controlled environments” is the comprehensive standard for cleanrooms. It currently regulates all aspects of the design, installation, and operation of cleanrooms in 15 parts. In the first part, nine cleanroom classes (ISO 1 to 9) are defined based on the previously valid US Federal Standard 209E.

- BS EN ISO 14159: Regulates the hygiene requirements for the design of machines and transport equipment.

Cleanroom classes according to BS EN ISO 14644

For the nine cleanroom classes of the ISO standard, both the size and the number of particles in a cubic meter of room air are measured.

| Particle size in microns | ≥ 0,1 µm | ≥ 0,2 µm | ≥ 0,3 µm | ≥ 0,5 µm | ≥ 1,0 µm | ≥ 5,0 µm |

|---|---|---|---|---|---|---|

| ISO 1 | 10 | |||||

| ISO 2 | 100 | 24 | 10 | |||

| ISO 3 | 1.000 | 237 | 102 | 35 | ||

| ISO 4 | 10.000 | 2.370 | 1.020 | 352 | 83 | |

| ISO 5 | 100.000 | 23.700 | 10.200 | 3.520 | 832 | |

| ISO 6 | 1.000.000 | 237.000 | 102.000 | 35.200 | 8.320 | 293 |

| ISO 7 | 352.000 | 83.200 | 2.930 | |||

| ISO 8 | 3.520.000 | 832.000 | 29.300 | |||

| ISO 9 | 35.200.000 | 8.320.000 | 293.000 |

For cleanrooms classes ISO 1-3, particles must not be larger than 0.5 μm and present in such a low concentration that the strictest hygiene regulations are met.

For most industrial companies, ISO 7/8/9 cleanrooms are sufficient. Only semiconductor and chip manufacturing typically require cleanrooms of class ISO 5 or lower.

Cleanroom classes according to GMP

In the GMP (Good Manufacturing Practices) guidelines, a distinction is made between four different cleanroom classes with the letters A to D. While A stands for the highest purity, a class D cleanroom has the lowest requirements. For classification, the concentration of particles in the air is measured in both resting and operating modes.

GMP cleanrooms require more stringent levels of control and compliance. All cleanrooms must be ISO-certified, but not all cleanrooms will qualify for additional GMP certification.

| Particle size in microns | ≥ 0,5 µm | ≥ 5,0 µm | ≥ 0,5 µm | ≥ 5,0 µm |

|---|---|---|---|---|

| A | 3.520 | 20 | 3.520 | 20 |

| B | 3.520 | 29 | 352.000 | 2.900 |

| C | 352.000 | 2.900 | 3.520.000 | 29.000 |

| D | 3.520.000 | 29.000 | No limit | No limit |

| State | Dormant state | Dormant state | In operation | In operation |

Since this classification is mainly used in the pharmaceutical and food industries, the microbiological contamination of the air is also included. However, the specified limits are only a recommendation, as legal requirements are laid down in industry-specific laws and standards.

All work equipment and parts used in the cleanroom enter the room through so-called material locks. Permissible contaminants get smaller and smaller from ISO 9-1, which is reflected in an increase in air purity.

Therefore, for example, pallet trucks are not permitted in the lowest cleanroom classes, where goods and materials must be transported manually.

What should be considered when setting up a cleanroom?

Any superfluous object in a cleanroom can interfere with the airflow necessary for cleaning, so you should limit your cleanroom equipment to only the most necessary items. Both tools and furnishings should be made of abrasion-resistant materials to minimise particles sticking to surfaces – this could include using stainless steel cabinets or worktables with a melamine-coated worktop.

Furnishings, as well as flooring and wall cladding, must be smooth and without seams so that no particles can settle. Materials should also be easy to clean and, if necessary for the respective work area, disinfected.

When selecting the right work chairs, antistatic materials and a construction with closed, smooth surfaces are particularly important. In case of doubt, seat cushions must be sealed with a plastic layer. Additional work materials such as notebooks and paper must also be suitable for use in cleanrooms.

Access to cleanrooms with particularly strict cleanliness requirements is usually achieved via separate zones with gradually increasing cleanroom grades, to guarantee the freedom from contamination necessary for the work.

After working with potentially hazardous products, sufficient disinfection of work clothing and work materials is also necessary. For the safety of employees, clearly visible and straightforward safety signs should be used.

Suitable pallet trucks and transport equipment for cleanrooms

To meet the prescribed requirements in cleanrooms, it is important to not only set up the rooms correctly but also to use suitable transport equipment such as pallet trucks, transport carts or transport trolleys.

After all, transport equipment moves sensitive components, tools and work equipment not only within cleanrooms, but also between different operating areas. To avoid the risk of cross-contamination during transport, all equipment must be suitable for operation in cleanrooms.

Transport equipment needs to comply with the hygiene regulations according to BS EN ISO 14159. An example would be a pallet truck made of stainless steel: The industrial trucks are resistant to chemicals, acids, alkalis and moisture and can be cleaned intensively and hygienically.

The stainless steel of the pallet truck housings is also smooth and abrasion-resistant so that no particles can be deposited. Closed fork tips also protect the transported goods from contamination. To prevent floor surface contamination, stainless steel pallet trucks and transport devices can also be equipped with abrasion-resistant and smooth nylon rollers.

Special transport trolleys must be used for the transport of decontaminated components from clean rooms to production or other operating areas. Depending on the design, closed stainless steel trolleys protect against the ingress of dust particles and are also available with electronic locks. Transport trolleys with exhaust air systems, in which the outside air is filtered via a pre-filter and a HEPA filter, can also be used for cleanroom products.

FAQ for cleanrooms

A cleanroom is an enclosed, insulated work area in which the concentration of airborne particles (aerosols) is kept at a particularly low level by special ventilation systems and access locks.

Highly sensitive products in the semiconductor, food or pharmaceutical industries must be protected from contamination by tiny particles invisible to the naked eye. This is because even minimal contamination can have a detrimental impact on the quality of the product and its function. Only in a cleanroom can the highest hygienic conditions be created.

Particularly important is the BS EN ISO 14644 standard for cleanrooms and associated cleanroom areas, as well as the Guidelines for Good Manufacturing Practice (GMP). In these standards, you will find all the important rules relating to the cleanroom – from the criteria for cleanroom classification to instructions on design and the right equipment to safe use by employees.

According to BS EN ISO 14644-1, a distinction is made between nine cleanroom classes (ISO 1 to ISO 9), whereby cleanrooms of class ISO 1 meet the highest requirements for air purity. The GMP guidelines provide a classification of four cleanroom classes (A to D) for which the particle concentration is measured in both resting and operating conditions. Since it is primarily aimed at the pharmaceutical industry, information on contamination with germs and microorganisms is also provided.

Certification by independent experts from recognized testing bodies ensures that ISO or GMP standards are complied with. This certificate is required to objectively prove the suitability of the operating facilities to customers and business partners.

Image source:

© gettyimages.de – gorodenkoff