Table of contents

Construction has always been one of the industries where occupational accidents, serious injuries or fatalities occur most frequently. For the 2019/20 year alone, the Health and Safety Executive reported 61,000 accidents and 40 fatalities. To prevent accidents, employers are obliged to have a risk assessment carried out. This involves identifying and assessing all sources of danger in the field of work – and determining appropriate measures to ensure the safety of employees. In this guide you can discover which factors play a role and which legal principles apply.

Construction sites pose an increased safety risk

Regardless of the industry, every company is obliged to carry out a risk assessment for all processes. This includes, for example, the assessment of machines, internal traffic routes or storage facilities, but also the examination of ergonomics at the workplace or the effects of work on the mental wellbeing of employees.

On construction sites, an assessment of possible sources of danger and risk is particularly important. After all, working at great heights, using powerful machines, or handling hazardous substances can pose a major safety risk. This is confirmed by the HSE injury and fatality statistics of recent years. Most reportable occupational accidents occur in the building and construction professions. In order to protect the health of employees in construction, it is essential to assess and avoid possible hazards.

How does a construction risk assessment work?

The assessment must be carried out before work even starts on the construction site. This is because if you avert or reduce possible hazards with countermeasures from the outset, you can preventively protect the health of employees.

Due to the large number of different activities in the construction industry, it is hardly possible to find a generally applicable example for the risk assessment of a construction site. You can find more information on the HSE construction risk assessment page which details what you need to do to carry out a general risk assessment. This provides suggestions for determining individual risk factors, which differ depending on the task area.

These individual risk factors can include:

- Mechanical hazards

- Electrical hazards

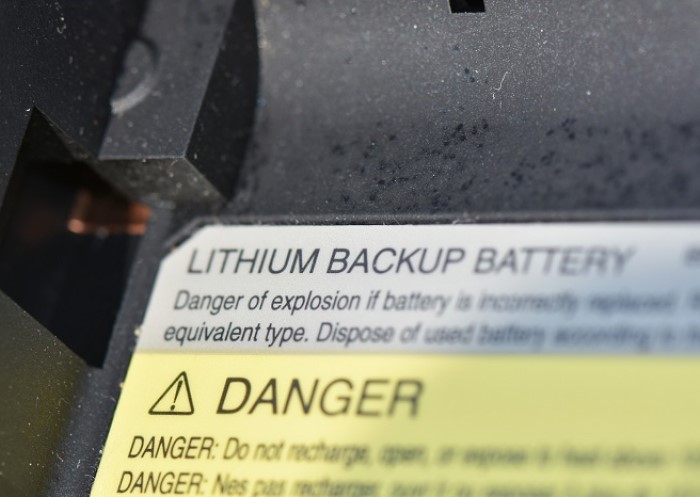

- Hazardous substances, fire and explosion hazards

- Biological hazards

- Thermal hazards

- Hazards due to physical effects

- Hazards due to working environment conditions

- Physical stress

- Psychological factors

- Working time arrangements

Supervisory authorities and insurance institutions are entitled to inspect occupational safety and health measures in companies and on construction sites. This includes checking whether the risk assessment has been carried out and documented in accordance with the regulations.

How possible hazards are assessed on the construction site

As important actors in occupational health, safety officers can play a central role in assessing and preventing hazards. Safety representatives have no authority to issue directives but offer an advisory and supportive role. For example, they ensure that safety standards are met, and that protective equipment is available and intact. They are the first point of contact for safety deficiencies, identify them and report them to superiors. The work is done on a voluntary basis and in addition to the actual work tasks.

Services of the safety officer during the construction risk assessment phase of a project include:

- Preparation

• Determine the area of consideration: Department, workplace, or activity to be assessed (comparable processes or working conditions can be grouped together)

• Create a basis of information: Relevant laws, internal company documents (inspection records of machines, lists of hazardous substances, staff sickness and accident reports, etc.), manufacturer’s information on machines and work equipment - Identify hazard

Identify all factors that pose a hazard in the previously identified area, e.g.:

• Activity-related: Working at height, working alone, hygiene requirements, handling hazardous substances.

• Ergonomic: Workplace design, work equipment

• Organisational: Working time, procedures, and processes

• Physical and psychological effects of work

• Consider not only employees, but also visitors or uninvolved third parties, if necessary

Hazards are determined by site inspection, testing of work equipment, questioning of employees. - Assess hazards

• Assess the risk with a uniform scale (e.g., assign a numerical value from one to five to indicate low to high)

• Indicate whether protective measures are already implemented and whether they are sufficient - Identify protective measures

• Determine new measures and follow the STOP principle (outlined below)

• Record responsible persons and time frame for implementation (if necessary, draw up a plan of measures for complex measures) - Implement measures

• Prioritise measures according to risk assessment

• Qualification of staff (training, further training, instruction) - Check

• Check implementation of measures

• Assess success

• If necessary, determine further protective measures - Documentation

• Document the results of the inspection

• Confirm inspection with date and signature

What protective measures should follow the risk assessment?

The protective measures that are determined within the risk assessment are based on the type and scope of the identified potential hazards. You must always proceed according to the so-called STOP principle:

- Substitution: Stop the activity (or stop using certain raw materials) and replace it with a process that poses less risk

- Technical measures: Structural or procedural changes that better protect the employee (e.g., protective walls, extraction of fine dust)

- Organisational measures: Changes in work procedures that ensure that employees are exposed to the hazard only when absolutely necessary (e.g., access restrictions, increased maintenance intervals, limited working time)

- Personal measures: Provision of personal protective equipment (PPE) such as respiratory protection, safety goggles, or fall protection

It is important that you consider these measures according to their order of priority. This means that you must always first consider whether substitution of the activity or work equipment is possible. Only if this is proven to be impossible can you take protective measures of the level below. For example, you may only oblige employees to wear PPE (personal protective equipment against falls from a height) if neither scaffolding can be erected on site, nor any other structural protection.

Legal requirements for risk assessments in the construction industry

The legal basis of risk assessments on construction sites is The Health and Safety at Work etc Act 1974. According to this, the employer must determine the hazards to which workers are exposed during the performance of their work. Both the risk assessment itself and the occupational safety measures derived from it must be fully documented and regularly checked to ensure that they are up to date.

In addition, there are further rules and regulations that build on the basic provisions of The Health and Safety at Work etc Act 1974, including:

- The Management of Health and Safety at Work Regulations 1999, also known as the ‘Management Regs’, which came into effect in 1993. The main employer duties under the regulations include making risk assessments for thehealth and safety of its workforce, and to act upon risks they identify, so as to reduce them (Regulation 3). It also states that employers should appoint competent persons to oversee workplace health and safety and provide workers with information and training on occupational health and safety

- The Workplace (Health, Safety and Welfare) Regulations 1992 require employers to provide adequate lighting, heating, ventilation, workspaces, staff facilities, including toilets, washing facilities and refreshment. It also outlines the need for safe passageways

- The Personal Protective Equipment at Work Regulations 1992 require employers to ensure that personal protective equipment (PPE) is provided free of charge ‘wherever there are risks to health and safety that cannot be adequately controlled in other ways.’

- The Manual Handling Operations Regulations 1992 require employers to avoid (so far as is reasonably practicable) the need for employees to undertake any manual handling activities involving risk of injury. They should also make assessments of manual handling risks, and try to reduce the risk of injury

- The Provision and Use of Work Equipment Regulations 1998 require employers to ensure the safety and suitability of work equipment, properly maintain the equipment, irrespective of how old it is, and provide information, instruction, and training on the use of equipment.

- The Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 1995 require employers to report a wide range of work-related incidents, injuries and diseases to the Health and Safety Executive (HSE), or to the nearest local authority environmental health department

FAQ for construction risk assessment

In general, every company is obliged to carry out a risk assessment for all processes and workplaces. This is particularly important on construction sites, because this is where most accidents involving personal injury occur.

In order to keep the risk of accidents as low as possible, an assessment of possible hazards must be carried out in the course of setting up the construction site before work on the site even begins.

The employer must determine the hazards to which workers are exposed when carrying out their work. In doing so, they must call in trained experts, e.g. a company doctor or an occupational safety specialist. These experts are involved in both the preparation and the updating of a risk assessment.

If several companies are employed on a construction site at the same time, an expert in charge can be appointed jointly.

As well as the Health and Safety at Work Act 1974, the following laws and regulations apply in the UK for construction site safety:

• The Management of Health and Safety at Work Regulations 1999

• The Workplace (Health, Safety and Welfare) Regulations 1992

• The Personal Protective Equipment at Work Regulations 1992

• The Manual Handling Operations Regulations 1992

• The Provision and Use of Work Equipment Regulations 1998

• The Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 1995

Please note: The regulations mentioned above represent only a selection of the most important legal requirements. Please refer to the listed organisations and directives for more detailed information. If in any doubt, consult experts or contact the relevant regulatory authorities.

Image source:

© gettyimages.de – dardespot