Table of contents

In various trades, construction, and production businesses, the lever effect or leverage is used with lifting tools such as crowbars, spanners o crane systems to simplify various assembly and construction work as well as load transportation. Leverage is also used for power transmission on machines, allowing in-house processes to be carried out safely and comfortably. To achieve this, the lever force or various lever forces must be calculated using leverage formulas.

The law of leverage as the basis for calculating the leverage force

Leverage is the force needed to lift and, if necessary, move loads. This is achieved using a lever, which in physics and engineering is technically known as a force transducer. It works by a rigid lever body tipping on an axis – in the same way as a seesaw.

The lever law takes into account both one-sided and two-sided levers. What all levers have in common is that they can be used to change the magnitude and direction of forces. The lever effect makes it possible to lift and move heavy loads with comparatively little effort.

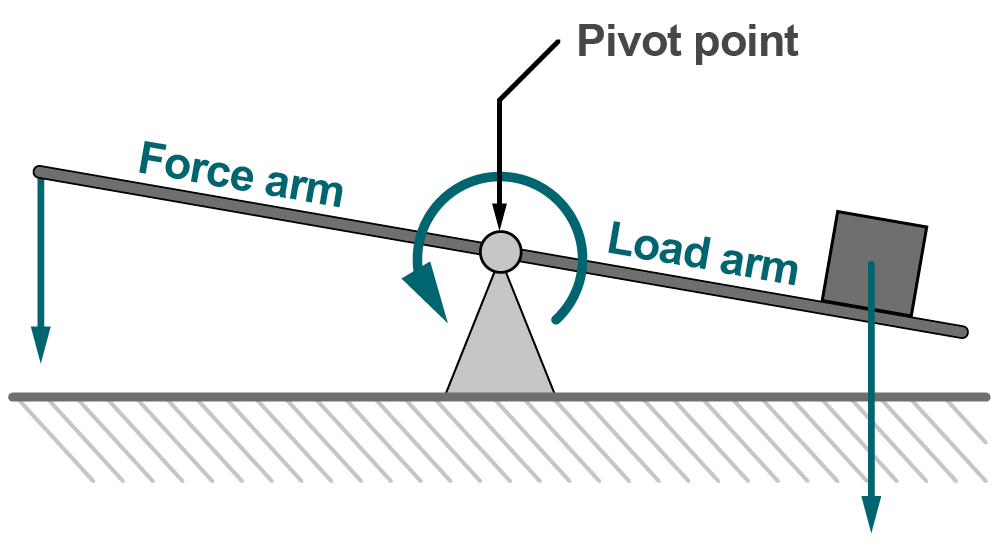

The lever force is defined and calculated using the lever law. This ancient law can be expressed simply with the following formula for calculating lever force:

Force x Force Arm = Load x Load Arm

The load arm defines the side on which the load to be moved is located. The force or power arm defines the side on which the moving force is applied. The so-called fulcrum or pivot point is the point around which the lever can turn. The torque, or rotational force, is the rotational effect that occurs when a lever is moved on one side of the pivot point with a certain force application. The longer the lever, the greater the force effect at the pivot point. Depending on the direction of rotation from the pivot point, right-rotating and left-rotating torques are distinguished.

Calculating lever force for one-sided levers

One-sided levers are characterised by:

- Load and force arm coincide, i.e., the lever forces act only on one side of the pivot point

- The pivot point is at one end of the lever arm

- The forces act in one direction

Practical example of a one-sided lever

A typical practical case of a one-sided lever is a screwdriver. The rotational movement of the lever transfers a tensile stress to the screw; when loosening the screw, the tensile stress decreases. To calculate the necessary lever force for one-sided levers, this formula can be applied:

τ = r x F

Where:

τ = Torque in Nm

r = Length of the lever arm in m

F = Force in N

Example calculation: A screwdriver with a lever length (r) of 0.6 m is to be used to tighten a machine screw with a torque (τ) of 38 Nm. The necessary lever force can be calculated as follows:

F = 38 Nm / 0.6 m

Result: The necessary lever force is 63 N.

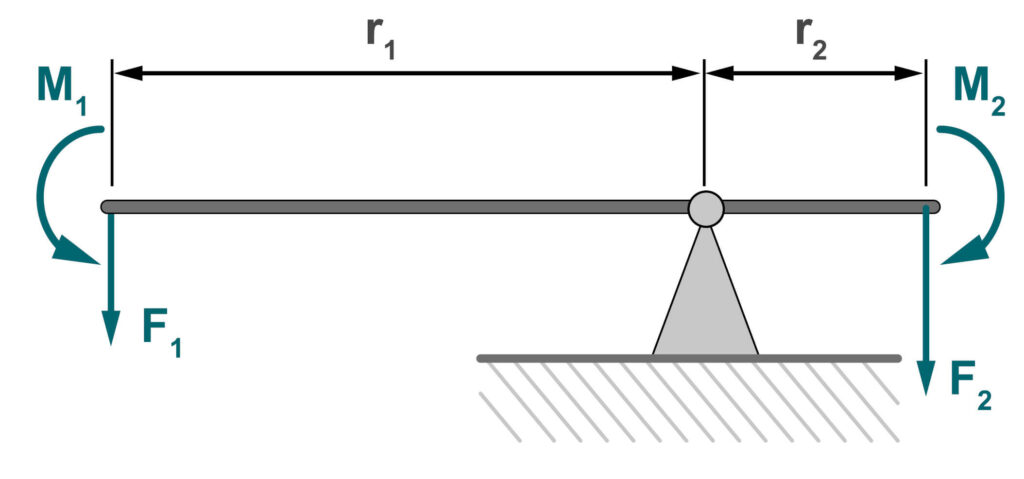

Calculating lever force for two-sided levers

Two-sided levers differ from one-sided levers in that:

- The force application points are on both sides of the pivot point

- The forces act in two directions

Practical example of a two-sided lever

Tools such as combination pliers are a typical two-sided lever as there are two lever arms opposite each other at the pivot point. Accordingly, the lever forces act in two directions here.

F1 x r1 = F2 x r2

Where:

F1 = Lever force 1

F2 = Lever force 2

r1 = Length of lever arm 1

r2 = Length of lever arm 2

Example calculation: We want to determine the lever force F1 for pliers with F2 = 500 N and r2 = 0.5 m, as well as r1 = 0.1 m. After rearranging the formula, the lever force for this two-sided lever can be calculated as follows:

F1 = 500 N x 0.5 m / 0.1 m

Result = 2500 N

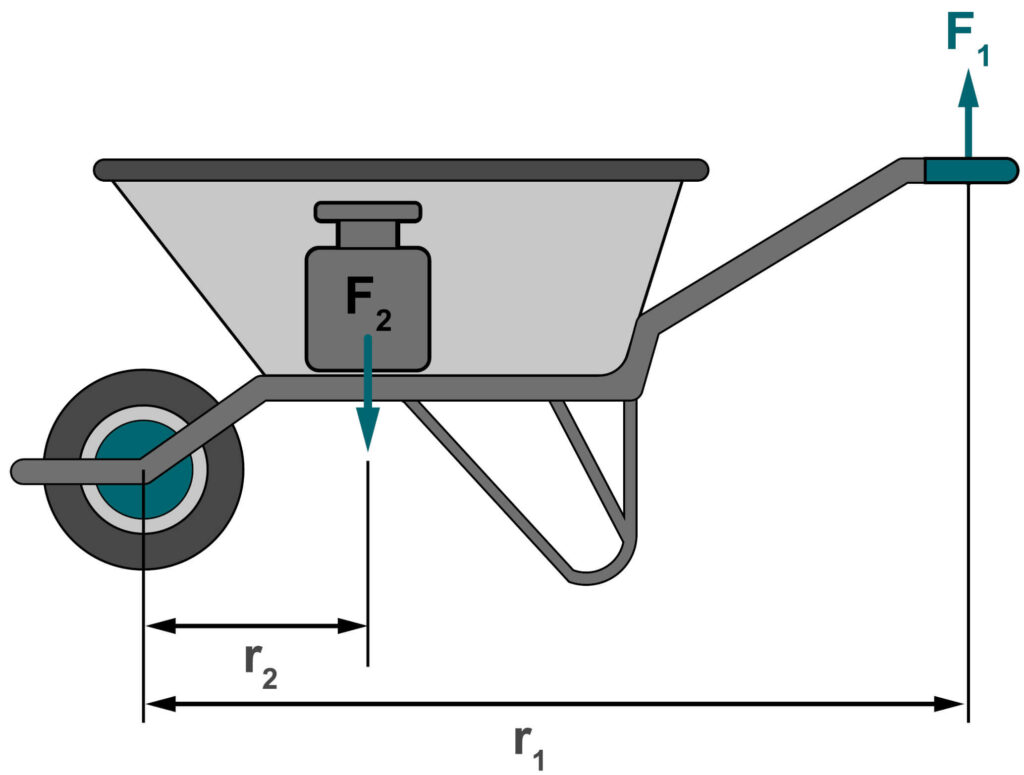

Using the lever effect, five times as much force can be generated on the second force arm. The formula for calculating the lever force on two-sided levers can also be applied to one-sided levers. For example, if you need to move a loaded wheelbarrow, both forces act on one side, but due to the loaded weight, there are two lever arms of different lengths.

If levers are not designed as straight devices, they can also be referred to asbent levers or angle levers. The latter are used in inclination scales, for example. With all types of levers, the friction at the pivot point must be taken into account in addition to the lever force. If the lever is turned over the axis, part of the energy used is converted into heat. Therefore, depending on the material of the lever and the load, an additional force is necessary to the required lever force.

Lifting equipment uses leverage to move heavy loads

Hoists use the leverage effect described above to reduce the amount of force needed to lift and move heavy loads. These include both manually operated and electro-hydraulic lifting systems, as well as hoists with and without a tilt function. Hoists can be found in logistics as well as on construction sites and combine a high lifting capacity with easy and comfortable handling. Typical hoists in operation include:

- Lever and rope hoists

- Electric stacker trucks

- Crane systems

- Material lifters

- Pallet lifters

- Level lifter

- Stacker trucks

- Electric chain hoists

Due to the differing power transmission ratios, hoists can facilitate work in many operational areas. They contribute to effective and safe work processes and increase the handling speed in warehouses and production facilities. In addition, operating costs can be significantly reduced through the use of high-quality hoists.

FAQs about leverage and how to calculate it

Leverage is the force needed to lift and, if necessary, move loads. This is achieved using a lever, which in physics and engineering is technically known as a force transducer. The rigid lever body can rotate around its own axis, similar to a seesaw. The lever law takes into account both one-sided and two-sided levers. The lever effect makes it possible to lift and move heavy loads with comparatively little effort.

To calculate leverage, you must use the lever law. Leverage can be calculated for one-sided levers with additional weight and two-sided levers using this leverage formula:

Force x Force Arm = Load x Load Arm

For one-sided levers where torque plays a role, the formula to calculate leverage is:

Torque = Lever Arm x Force

Levers are divided into one-sided and two-sided levers. One-sided levers are characterised by:

• Load and force arms coincide, i.e., the leverage forces act only on one side of the pivot point

• The pivot point is at one end of the lever arm

• The forces act in one direction

Two-sided levers, on the other hand, are characterised by:

• The force application points are on both sides of the pivot point

• The forces act in two directions

Image source:

© gettyimages.de – PRImageFactory