Table of contents

Welding is the process of joining two metals together. This process primarily involves heating the metals beyond their solidus temperature, causing them to lose their solid form and fuse together. The welding method you choose depends on whether you’re working on a personal project or for commercial purposes, as well as the types of materials you want to join. Different welding techniques are suitable for various applications. In our guide, we will answer the questions, what is welding, what are the different types of welding and which processes are appropriate for what applications, as well as the standard safety precautions you should take.

What is the difference between soldering and welding?

The goal of soldering and welding metal is the same, that being the joining of two or more separate workpieces. However, the working processes vary significantly. A major difference lies in the working temperature and the resulting strength of the material joint – both of which are considerably higher during the welding process than with soldering. In addition, depending on the type of weld, you can often do without a fastener, however, this is not possible with soldering.

Welding isn’t limited to metals anymore. Thanks to a wide range of welding processes, it’s now possible to weld glass and plastic as well. For example, these methods are used to join fibre optic cables or connect PVC flooring pieces. This expansion of welding capabilities has opened up new possibilities in various industries and applications, allowing for more versatile and efficient joining processes across different materials.

Different types of welding

There are a variety of different welding processes that can be used for a wide range of purposes. A broad distinction is typically made between fusion welding processes and press welding processes.

- In fusion welding, the metals are bonded together through heating and melting. Some processes use filler materials such as welding rods for gas fusion welding, rod electrodes for manual arc welding, or wire electrodes for MIG and MAG welding.

- In press welding, the material joint is created without filler materials and via compression forces. This requires a great deal of force which, nowadays, is almost exclusively generated by machines.

Overview of the most important fusion welding processes

The most popular fusion welding processes are MIG, MAG, and TIG welding. These are preferred methods for both industrial and residential applications as they require minimal labour and produce high-quality results within a short processing time. The following table shows an overview of these procedures and their areas of application.

| Type | Process | Applications |

|---|---|---|

| Gas Fusion Welding / Gas Welding | Here you heat metal workpieces with the help of an open flame, produced with the gas acetylene. Materials are then joined either directly or with a welding wire. | Gas fusion welding is particularly popular in the private sector, as this technique requires little effort and no machines. |

| Manual Arc Welding | In manual arc welding, also known as MMA welding, an electrode-coated metal rod is manually added to the workpiece and the arc. During the heating process, the coating of the electrode melts and creates the protective slag. It is not necessary to add shielding gases. | The process is mainly used in steel and pipeline construction. It has the advantage that no shielding gas is required. Thus the welding process can take place indoors and outdoors. |

| MIG & MAG Welding | The metal inert gas (MIG) and metal-active gas (MAG) welding processes belong to the category of arc welding. Here, a wire electrode is added to the arc and the workpiece as a filler material. By using shielding gases, you create the necessary protection for the joint. The difference between the two variants lies in the use of shielding gas: • In MAG welding (metal-active gas), the gas actively reacts with the melt pool. • In MIG welding (metal inert gas), the gas does not actively react with the melt pool. | These processes are often used in tank and pipe production, as well as in precision engineering and nuclear technology. They are popular due to their speed and effectiveness and require less ongoing maintenance. |

| TIG Welding | In tungsten inert gas (TIG) welding, the arc is generated between the workpiece and a tungsten electrode. As with MIG welding, you add an inert gas. The difference between MIG and TIG welding is that, since the tungsten electrode does not melt, an additional welding wire is used to create the connection. | This process is generally used when the demands for quality and appearance are very high. Typical areas of application are steel and pipeline construction, power plant construction or medical technology. |

| Submerged Arc Welding | In this welding process, a mineral powder is added in addition to the workpiece and the wire electrode. This then forms the slag that covers the melt pool. | Submerged Arc Welding is mainly used for alloyed and unalloyed steels in steel, bridge, or container production. |

| Laser Welding | In laser welding, the heat is focused on a very small surface area. This leads to the melting of the material and thus to the connection of the two workpieces. | This method is often favoured for its fast and highly precise results and is a frequently used technique. |

An overview of the most important press welding processes

Press welding processes are best suited for industrial and mass production. These can be automated with machines and ensure flawless results. Here is a brief overview:

| Type | Process | Applications |

|---|---|---|

| Fire Welding | Fire welding is the oldest welding process. Here, pieces of iron are heated to melting point and joined by hammer blows. | Nowadays, fire welding is only used in the traditional production of weapons or tools. |

| Friction Welding | With the help of machines, friction between materials is generated at very high speeds. The resulting heat and pressure successfully bond the materials. | This process is used in industries such as aviation, aerospace or automotive production. The advantages are flawless welding quality, short welding time, and independence from shielding gases and filler materials. |

| Resistance Welding | The metals are bonded together by a mixture of force and electrical resistance heating. | This process is particularly suitable for thin sheet metal and, just like friction welding, is often employed in the aviation, aerospace or automotive industry. |

MAG welding: a step-by-step guide

Our instructions will guide you through all the necessary steps of MAG welding.

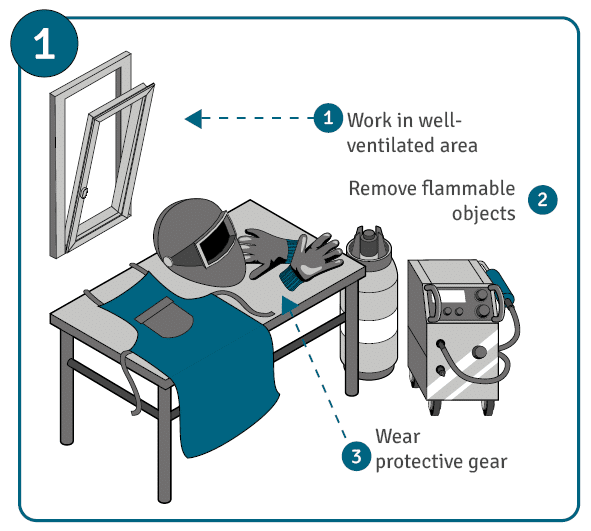

- Take safety precautions

To avoid accidents during welding, we must first ensure we are following all safety precautions. Remove any flammable objects from your environment and ensure adequate ventilation. Wear flame-retardant clothing and gloves and a welding safety helmet.

To avoid accidents during welding, we must first ensure we are following all safety precautions. Remove any flammable objects from your environment and ensure adequate ventilation. Wear flame-retardant clothing and gloves and a welding safety helmet. - Inserting welding wire into the torch

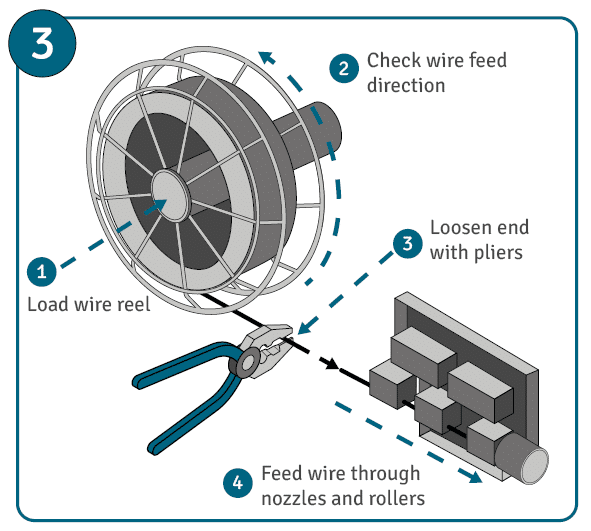

Place the wire roll into the welding torch pick-up device and loosen the end with pliers. The beginning of the wire must now be passed through the wire feed nozzle and conveyor roller into the wire infeed nozzle.

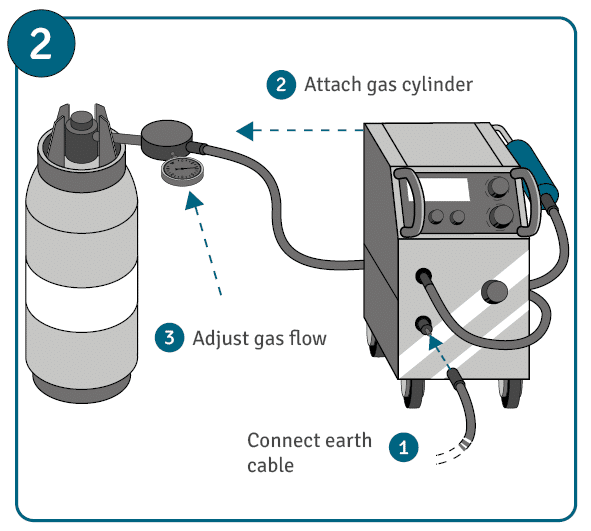

Place the wire roll into the welding torch pick-up device and loosen the end with pliers. The beginning of the wire must now be passed through the wire feed nozzle and conveyor roller into the wire infeed nozzle. - Putting the MAG system into operation

Now you can connect ground cables, as well as the gas cylinder and the welding torch. Please note: The gas flow can be adjusted on the pressure gauge. The general rule for this is usually 10-12 l/min. As a guide for the amperage, you should use 30-40 amps per mm of sheet thickness.

Now you can connect ground cables, as well as the gas cylinder and the welding torch. Please note: The gas flow can be adjusted on the pressure gauge. The general rule for this is usually 10-12 l/min. As a guide for the amperage, you should use 30-40 amps per mm of sheet thickness. - The welding process

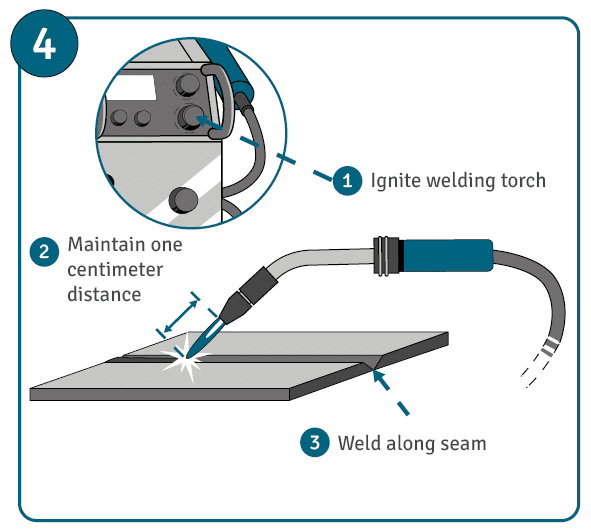

Now, press the button on the welding torch to start the process. Hold the torch approx. 15° against the direction of welding, at a distance of around one centimetre from the workpiece.

Now, press the button on the welding torch to start the process. Hold the torch approx. 15° against the direction of welding, at a distance of around one centimetre from the workpiece.

Push welding is an effective and simple technique. Simply guide the burner evenly along the connection point.

Be sure to pay attention to your wire feeder. If the speed is too high, unsightly unevenness can form, whereas if it is too low, the joint will prove ineffective.

Safety precautions for welding

Regardless of the welding processes being deployed, a number of accidents can occur. In order to keep the risk as low as possible, appropriate safety precautions are essential. You will need the following to ensure an accident-free welding process:

Personal protective equipment

To prevent injury from sparks or UV light, you need suitable protective equipment.

This typically consists of flame-retardant clothing including gloves and a welding safety helmet or welding goggles. A welding safety helmet protects the head from radiation, fire, and sparks, as well as from any materials flying around.

If you use welding techniques in which the skin does not need UV protection and the head is not exposed to any other hazards, welding goggles may be sufficient. However, both welding helmets and welding goggles must be equipped with an infrared (IR) and UV filter in all cases.

Ventilation

The use of gases can lead to a lack of oxygen during the welding process. The fumes released during the welding process are also dangerous for the welder, as the gas particles can settle into the alveoli of the lungs. It is therefore essential to carry out any welding processes in a well-ventilated room or area. If natural ventilation is not possible, you should use technical equipment such as fans or blowers. However, the most effective method is spot extraction. This technique extracts the gases directly at the torch, preventing them from spreading throughout the room.

Welding curtains

Welding safety curtains can also be used. These ensure that no sparks leave the work area and, depending on the protection level, can also filter out UV radiation.

FAQ on welding processes

Metal is not the only material that can be welded. Thanks to an extensive range of welding processes, it is now possible to weld glass and even plastic. For example, fibre optic cables or PVC floors can be connected via welding.

MIG and MAG welding processes belong to the category of arc welding. Here, the concentrated arc provides a high deposition rate and the necessary protection for the connection point is created by adding shielding gases.

The difference between the two variants lies in the use of shielding gases – in MAG welding (metal-active gas), the gas actively reacts with the melt pool, in MIG welding (metal-inert gas) it does not actively react with the melt pool.

TIG welding (tungsten inert gas welding) involves using a non-consumable tungsten electrode and an inert gas. A filler metal is typically used, unlike in MIG welding where the electrode also acts as the filler material.

Laser welding (also known as laser beam welding or LBW) is a non-contact form of welding which uses a highly targeted and precise laser beam to deliver a concentrated heat source. This allows for particularly deep and narrow joints to be created.

To avoid accidents during welding, both the welder and the work area must be adequately protected. This requires flame-retardant clothing, head, and eye protection, as well as sufficient ventilation.

Image source:

© gettyimages.de – cristianl