Table of contents

In logistics, industrial goods are usually loaded on pallets to transport and store them quickly and efficiently. To prevent the goods from moving during transport, they must be securely fastened. Stretch wrapping a pallet allows individual items to be packaged together to create a solid load unit. When done correctly, wrapping pallets can help ensure your goods arrive at their destination undamaged.

In this guide, we will show you how to wrap a pallet in shrink wrap, what methods and devices are available to assist you, and which relevant guidelines apply to the procedure.

What are the benefits of wrapping pallets with plastic wrap?

Shrink wrapping pallets offers the following benefits:

- Goods are secured against slipping or tipping during transport and storage by creating a solid load unit

- Compact load units are particularly stable and can withstand even strong forces such as harsh seas or high winds during transport

- Goods therefore reach their destination safely and in a better condition

- This reduces unnecessary costs due to complaints or inventory spoilage and improves customer satisfaction

Preparing and securing your pallets

Before you shrink-wrap a pallet, suitable pallet accessories should be used to secure the load as follows:

- Place anti-slip paper between the pallet and the first layer of goods.

- Once the first load of goods is on the pallet, place anti-slip sheets between each subsequent layer.

- Protective corners, strapping, and edge protectors provide additional stability and protection.

- Cover the top goods with a masking film before starting the actual wrapping process.

How to wrap a pallet by hand

For manual pallet wrapping, you need the right technique in addition to a hand dispenser and a suitable stretch film. The following instructions show you how to apply the film correctly to attach your goods to the pallet securely:

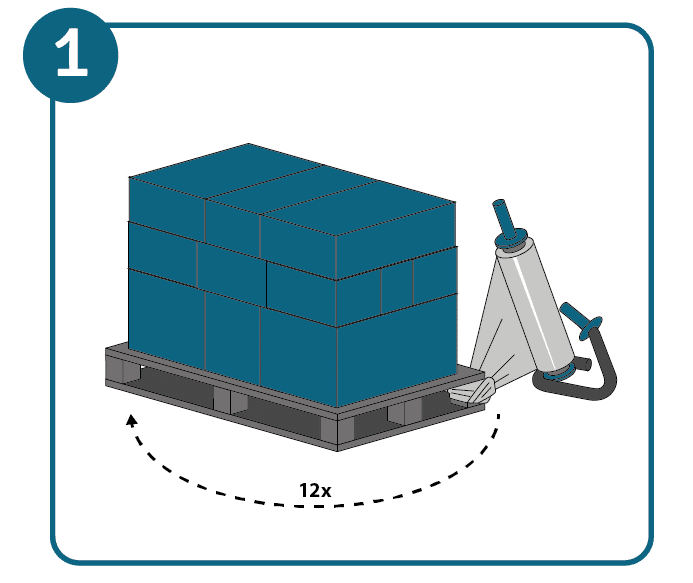

- Foot wrap

Knot the end of the film at one corner of the pallet. Now wrap the lower area of the goods approximately eight to twelve times to securely connect the goods to the pallet.

Knot the end of the film at one corner of the pallet. Now wrap the lower area of the goods approximately eight to twelve times to securely connect the goods to the pallet. - Middle wrap

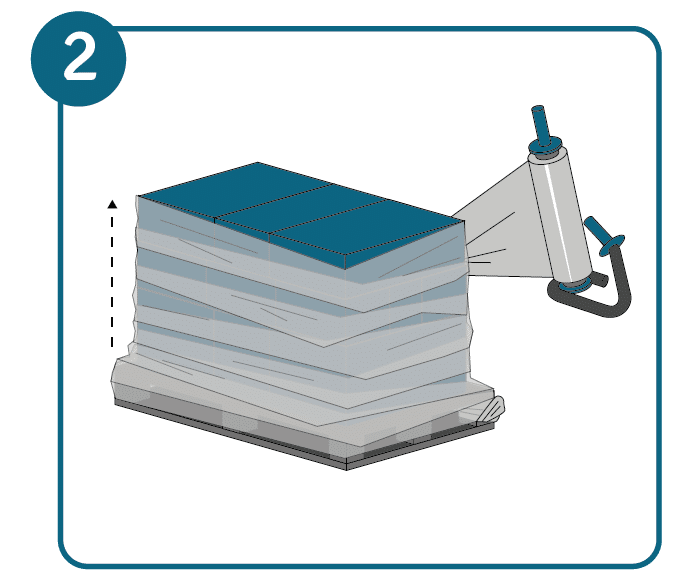

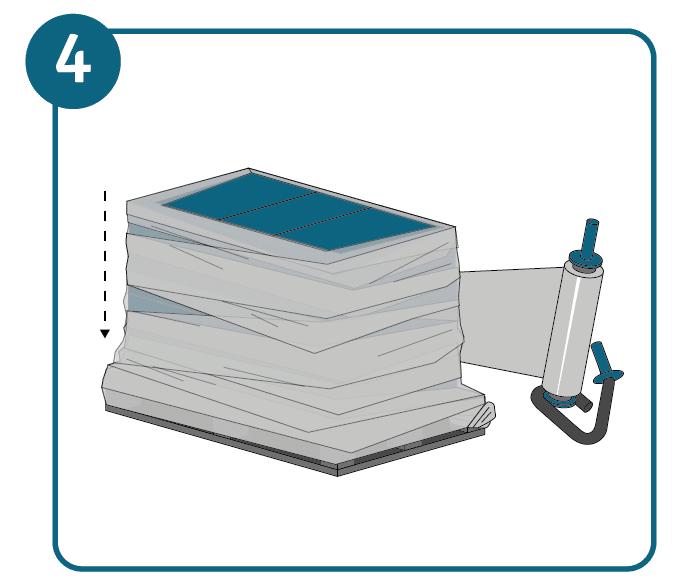

Wrap the stretch film in a spiral around the load units from the foot upwards. Each new layer should overlap the last one at least halfway.

Wrap the stretch film in a spiral around the load units from the foot upwards. Each new layer should overlap the last one at least halfway. - Head wrap

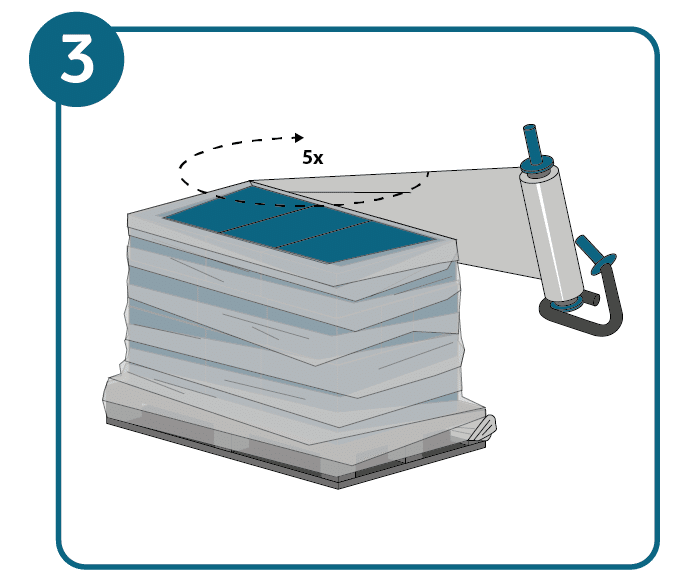

Once you reach the top of the load, wrap it four to five times.

Once you reach the top of the load, wrap it four to five times. - Cross wrap

Then stretch downwards again in a spiral. This will ensure the middle area is doubly secured. You should also wrap the foot area again.

Then stretch downwards again in a spiral. This will ensure the middle area is doubly secured. You should also wrap the foot area again.

Special care must be taken when wrapping the foot as this is one of the biggest potential structural weaknesses. Make sure that the foot area is secured with an adequate number of wraps so that the load unit can be transported safely and remain secure during transportation.

Interesting facts about stretch film used for wrapping pallets

Stretch films are flexible, stable, and lightweight materials that are usually transparent, but are also available in colour. Stretch films are offered as mini stretch films, hand stretch films, and machine stretch films. The material differs in its strength, resilience, and size.

All films are made of plastic polythene (PE), which is liquefied to produce various types of films. The quality of the PE used depends on the molecular structure and plays an important role in the resilience of the stretch film.

When choosing the right stretch film for shrink-wrapping pallets safely and effectively, keep two key points in mind:

- Select a film that’s suitable for your cargo type and weight

- Apply the film using the correct technique

Regardless of the quality, each stretch film must be pre-stretched to its strength limit to securely fasten your goods. Only when this limit is reached can it withstand high inertial forces. Until then, the material gives way even under slight force and is unsuitable for safely transporting boxes, crates or loose goods.

How to manually shrink-wrap a pallet with the correct film

For manual pallet wrapping, you can use standard films or pre-stretched film. However, pre-stretched films are typically recommended, as they offer the following advantages:

- Roll weight: If a roll of standard film weighs 4 kg, including the manual dispenser, then similar rolls of pre-stretched film will weigh approximately 2 kg. This makes manually wrapping pallets with pre-stretched film easier.

- Material thickness: Standard film is relatively thick compared to pre-stretched film – you need more storage space to use standard film.

- Material consumption: Wrapping pallets with pre-stretch film requires approximately 60% less material. Wrapping a pallet nine times with standard film requires about 300 grams of standard film, or approximately 120 grams with pre-stretched film.

- Cost: Due to the higher material consumption, the cost of standard film is about 33% higher compared to pre-stretched film.

That is why pre-stretched films should be used to secure the load. Especially if you work with a manual dispenser or a simple stretching machine without a pre-stretching function, because with manual pallet stretching it can be difficult to ensure the strength limit is uniformly reached.

Note: Applying the wrap by hand is mainly suited to protecting cargo from dust, dirt, and moisture. A pallet stretching machine, on the other hand, is more suited to securing goods for safe transport.

How to stretch wrap a pallet using stretch machines

Both automatic and manual pallet wrapping require the right technology. If you are using a pallet stretching machine, it is particularly important that you configure the system correctly. You should consider the following steps:

• Adjust and secure the stretch film as instructed

• Calculate the optimal application tension

Set the number of foot, middle and head wraps

What pallet stretching machines are available?

If you want to automatically shrink-wrap a pallet, you can choose from the following pallet stretchers:

| Stretch-roller Device | Functionality |

|---|---|

| Systems with brake roller | • The stretch film first runs over an electro-mechanical brake roller – this ensures a constant tension • The tensioned film is wrapped around the loaded pallet on the turntable • Only suitable for pre-stretched films |

| Pre-stretching systems without drive | • Suitable for non-pre-stretched films • Consists of two rollers that pre-stretch the film • The tension of the film during wrapping corresponds exactly to the degree of pre-stretching |

| Pre-stretching system with drive | • Two or more motor-driven rollers • The stretching force for wrapping can be set higher than the pre-stretching • Only suitable for particularly high-quality films |

FAQ about wrapping pallets

Businesses often wonder whether stretch wrapping pallets is a valid way to safely transport and store goods. The short answer is yes. The load can only slip or become damaged if mistakes are made during stretching. To transport goods safely with the help of stretch film and to determine who is responsible for securing the load, the following guidelines and standards should be followed:

• BS EN 415-8: This standard deals with safety requirements for automatic packaging machines including, but not limited to, machine design, installation, operation, maintenance, and cleaning.

• Pallet Safety PM15: This guidance covers general-purpose flat pallets and includes practical advice to industries and companies that regularly use pallets for storage and transport. Included is a recommendation that shrink-wrapping be used to secure pallets where the height exceeds the longest base dimensions of the pallet.

• EU Directive 2014/47/EU: The directive stipulates that “all actors involved in the logistics process […] must ensure that the cargo is properly packed and properly loaded onto a suitable vehicle” (paragraph 17). This is checked during technical road inspections by competent authorities and applies to any vehicle operating within the EU, regardless of country of origin. In the UK, DVSA officers perform a similar role and have the power to inspect commercial vehicles for health and safety compliance.

If you apply standard films by hand, it is unlikely you will be able to uniformly achieve the optimal level of tension. This means that manually applied, non-pre-stretched films can expand during transport and cause goods to slip. Pre-stretched film makes manual wrapping simple by already arriving at the optimal level of stretch.

You can achieve the greatest stability with a pallet stretching machine, as it stretches the film immediately during application and therefore develops the necessary tensile forces to secure the load. Manual pallet stretching is typically used more to protect against dust, dirt, and moisture than to secure the goods.

Please note: The regulations mentioned above represent only a selection of the most important legal requirements. Please refer to the listed organisations and directives for more detailed information. If in any doubt, consult experts or contact the relevant regulatory authorities.

Image source:

© gettyimages.de – dolgachov, endopack