Scissor lift platforms for material lifting in warehouses and production

Scissor lift platforms make it easy to lift palletised or individual goods to an ergonomic working height or to higher storage areas. Depending on the model and function, these electric lifting platforms can also be a practical addition to an automated process in a warehouse or industrial building. Use our buying guide to find the right scissor lift table for your needs.

1. Scissor lift platforms for versatile use in industrial processes

The scissor lifts available from Jungheinrich PROFISHOP enable you to lift loads on or in various load carriers such as pallets, outer packaging or pallet boxes to ergonomic working heights and higher. Mounted on at least two scissor-like beams, the lifting platform can either be screwed into the ground or installed in a pit for optimal use.

Our scissor lift platforms are available with different constructions, so they can conveniently be adapted to specific areas of application. Depending on the model, their lifting function works electrically or using compressed air and they are suitable for use in a range of applications including:

| Area of application | Details |

|---|---|

| Ergonomic work processes |

|

| Use as workbench or worktable |

|

| Replacement for dock levellers and ramp systems |

|

| Integration into automated processes |

|

2. How to choose the right scissor lift platform for your needs

In our range you will find a large selection of different scissor lift platforms which differ in their lifting range, load capacity and other parameters. In order to find the scissor work platform that suits your needs, there are some important selection criteria to consider:

- What weight capacity should the lift platform have?

- What lifting height or lifting range is required for your work tasks?

- What are the dimensions of the product and which platform size is suitable?

- Where will the scissor lift be set up (indoors or outdoors)?

- How will the scissor lift be loaded?

- Which drive should be used for the lifting function?

- Are certain safety features required?

Load-bearing capacity

In order to be able to lift and lower goods and merchandise safely and stably, a scissor lift platform may only be loaded with a specified maximum load. When selecting a suitable platform lift, you should therefore use the peak loads that occur in your operating process as the basis for your decision. The scissor lift platforms from our range offer a load capacity of up to 1000kg, depending on the model, and are therefore ideal for the vertical lifting of heavy loads.

When choosing a lifting platform with a suitable load capacity, the most important thing to take note of is how the weight will be distributed on the platform. For example, a scissor lift platform with a load capacity of 1000kg may no longer be sufficient for a load weight of 1000kg if the load is not evenly distributed on the platform. This is due to the interaction of the force arm and the lever arm: depending on where the load is placed on the platform, the scissor mechanics of the device are loaded differently. To prevent damage, BS EN 1570-1 specifies the following:

- If the entire platform is loaded evenly, the load capacity specified by the manufacturer is sufficient. In this case, a maximum load of 1000kg, for example, is suitable for a scissor lift platform with a load capacity of 1000kg.

- If the load is only placed on one half of the platform, the scissor lift must still be able to carry at least half the load weight. For example, if the scissor lift platform has a load capacity of 1000kg, only a maximum load weight of 500kg may be placed over half the platform length.

- If the load is only placed over half the platform width, the scissor lift must still be able to carry at least one third of the load weight. As an example: if the unit has a load capacity of 1000kg, only a maximum load weight of 330kg may be loaded on half the platform width. Conversely, this means if a load weighing 1000kg is to be placed across half the platform width, a model with a load capacity of 3000kg instead of only 1000kg is the right choice.

Lifting height

Whether a large or small lifting platform fits into your operating procedure depends not only on the load capacity but also on the lifting height. This can vary depending on the type and length of the scissor frame. At Jungheinrich PROFISHOP you can buy scissor lift platforms with a lifting height of up to 840mm. This enables you to adjust the platform to any desired ergonomic working height and higher or lower settings when needed.

Installation site

The scissor work platforms available in our store are suitable for use in dry indoor areas. However, some designs also allow use in damp or corrosive indoor areas or outdoor areas exposed to the weather. Designed for stationary use, our scissor lift platforms can be floor mounted or installed inside a pit. However, some units can also be picked up and moved by means of transport lugs for cranes or drive-in lugs for stacker trucks.

Loading

- In order to load or unload goods onto the scissor lift, industrial trucks such as pallet trucks or stacker trucks are usually required. Depending on the load weight, surrounding environment and the lifting platform model, the following options are possible:

- Direct entry with stacker or pallet truck: Here, the industrial truck is driven directly into the U-shaped recess of the pallet lift platform. The load carrier can then be lowered and set down comfortably and safely above the platform.

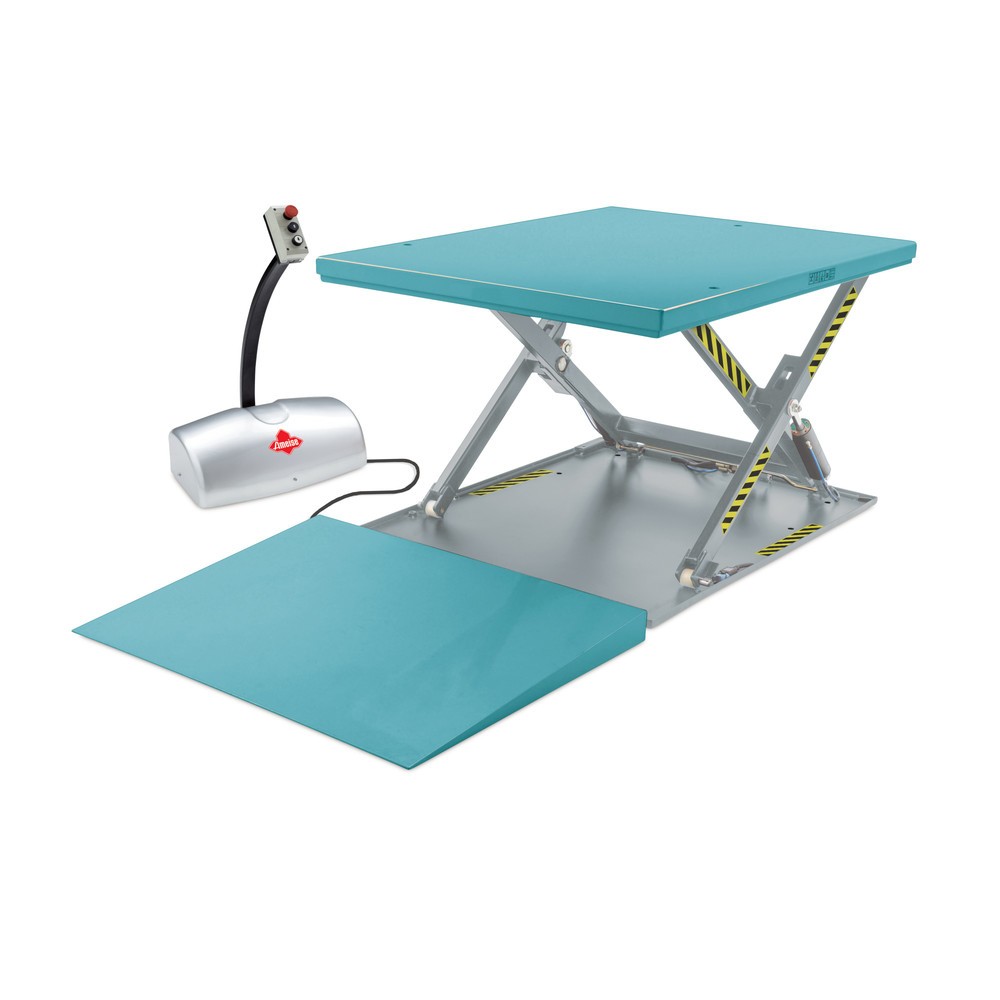

- Loading or unloading via drive-on wedge: These scissor lifts offer a closed platform, which prevents the forks of a pallet truck or stacker truck from driving into them directly. Instead, it is possible to drive up to the platform and remove or set down goods via a stable drive-on wedge.

- Loading or unloading with wide-gauge industrial trucks: The fork spacing on wide-gauge stacker trucks is greater than on standard versions. Scissor lifts with platforms no wider than 800mm, enable the forks of a wide-gauge truck to easily move to the left and right of the unit and place or pick up the palletised goods directly above the platform.

- Pit installation: In order to achieve barrier-free access to the platforms with industrial trucks, many of our scissor lifts are also suitable for pit installation. In this way, the base and platform are at the same height and can also be loaded and unloaded with pallet trucks.

Lifting functions

Our scissor lift platforms feature an electro-hydraulic lifting function which is operated by an electronic control unit. This requires minimal effort for operation and makes it easy to adjust the height of the scissor lift, with or without a load. Some of our models feature an external control unit, which enables device operation from a safe distance. Inspection supports are also fitted to ensure accidental lowering does not occur during servicing, while the protective frame provides additional safety.

Safety features for a secure work environment

Depending on the model you choose, the electronic scissor lift tables in our range are available with the following safety features:

| Safety feature | Details |

|---|---|

| Emergency stop function |

The emergency disconnect switch is attached to the operating unit: when pressed, all movements are immediately interrupted, as well as the power supply if necessary. |

| Safety contact strip |

The foot protection contact strip is located on the underside of the platform and triggers when touched if the specified foot clearance is not maintained. When triggered, the lifting or lowering movement is stopped immediately. |

| Heat protection for electric drive systems |

The heat protection prevents electrical systems from overheating and thus avoids short circuits or cable fires. |

| Key switch |

A scissor lift with a key switch can only be operated by inserting a key. This means that the unit can only be put into operation by authorised personnel. |

3. Work ergonomically with the right lifting platform

The scissor lift platforms in our range meet all required safety standards and are tested and certified according to BS EN 1570 of the European Committee for Standardisation (CEN). The devices are exclusively made of high-quality materials, such as powder-coated profile steel or tool steel and are processed to a high standard. This ensures for reliable and safe equipment that offers a long service life.

Flat scissor lift tables

You can buy flat scissor lifts from us with closed, U-shaped or E-shaped load platforms. This allows the load carriers of industrial trucks to drive directly into the recesses and load or unload the platform. Due to their low lifting height, the units are ideal for use as worktables or workbenches at an ergonomic working height. At a glance, the features of our flat scissor lift platform include:

| Parameter | Details |

|---|---|

| Application |

|

| Equipment features |

|

| Load capacity |

|

| Lifting range |

|

| Maximum lifting cycles |

|

| Lifting speed |

|

| Lowering speed |

|

| Scissor shape |

|

| Drive type |

|

Single scissor lift tables

The single scissor lift tables from our range are equipped with a closed load platform made of smooth sheet steel. The platform can be continuously adjusted in height. For maximum work safety, the upper and lower lifting positions can be mechanically locked. Some models are available with a key switch to ensure that only authorised personnel can operate the device.

| Parameter | Details |

|---|---|

| Application |

|

| Equipment features |

|

| Load capacity |

|

| Lifting range |

|

| Maximum lifting cycles |

|

| Lifting speed |

|

| Lowering speed |

|

| Scissor shape |

|

| Drive type |

|

4. FAQ for scissor lift platforms

Lift platforms can be used to lift and lower goods or merchandise. For stability during operation, lift tables are available as stationary equipment that can be fixed to the ground or lowered into a pit. Specific advantages of lift tables lie primarily in their wide range of application (depending on the model). They can be used:

- for ergonomic working at individually adjustable working heights

- as a workbench or worktable

- as a goods lift for material supply to e.g., conveyor lines or for loading and unloading shelves

- as a practical replacement for dock levellers and ramp systems

- within automated processes

When choosing a lifting platform, it is important to find one with the right maximum loading capacity. You should take note of the peak load requirements that are usually required within your operating process and use this as the basis for your decision. It is very important to understand how weight is distributed on the platform and how this can affect lifting capacity.

In principle, large and small scissor lift platforms can be used for lifting and lowering pallets – as long as they have a sufficiently large platform and a suitable load capacity. However, lifting and lowering palletised goods is particularly ergonomic with flat scissor lifts: the forks of pallet or stacker trucks can be inserted into the recesses of the U- and E-shaped platforms of flat scissor lifts and loads can thus be lowered directly above the platform.