How to find the right roller conveyor

Roller conveyors can be used to set up versatile conveyor systems that make it much easier for your employees to work on packing lines or in production. Roller conveyor tables operate exclusively on a slight incline and require a motor-assisted drive. They can therefore be used wherever boxes, small parts and storage containers of all kinds have to be transported between different workstations. The roller conveyors, which are available as straight lines and curves, offer many more advantages:

- Low maintenance, as no complex technology is installed

- Conveyed material is transported quietly and energy-efficiently even over long distances

- Speed individually adjustable via gradient

- Constant conveying flow possible

- Conveyor line can be easily adapted by conversion and extensions

- Flexible routing, both stationary and with flexible roller conveyors that can be adapted to the length of the line

1. Selecting conveyor tables suitable for transporting certain goods

A major advantage of heavy duty, industrial roller conveyors is that they are suitable for moving goods with different types of surfaces (depending on the model). These include goods with a flat, level base, longitudinal rails, ring bars or goods with a mesh or grid base. In this respect, they differ from mini conveyor belt rollers, which can only be used for moving goods with a flat base.

Nevertheless, the material to be conveyed is the most important criterion for buying the right roller conveyor. When selecting a model, the weight and dimensions of the goods to be conveyed are the most important factors: the centre distances of the rollers and the maximum load of the frame must also be taken into account. The conveyor should also be wide enough to accommodate the size of the goods that will be transported.

Rule of thumb: The goods being conveyed on a roller conveyor system should be in contact with at least three rollers at all times. This is the only way to ensure that the goods being conveyed can run over the conveyer at the necessary speed and that an even flow of material is achieved.

| Material to be conveyed | Suitable roller conveyors |

|---|---|

| Small goods and individual parts |

Mini and small roller conveyors: short distances between the individual rolling elements prevents small items from falling through. They can be used to transport goods with all types of bases, including longitudinal rails and grid surfaces. |

| Small goods with up to 40kg load weight per piece |

Lightweight roller conveyors: these models features larger distances between the rolling elements, as well as a larger roller diameter to achieve the necessary rotation. The conveyed material must have flat a flat, level base. |

| Heavy goods with an individual weight of up to 150kg |

Heavy duty conveyor rollers: the tracks on these models have sturdy steel conveyor rollers with a large roller diameter for heavy loads. Goods with all types of base surfaces can be transported on these units. |

| Variable sizes of the conveyed material |

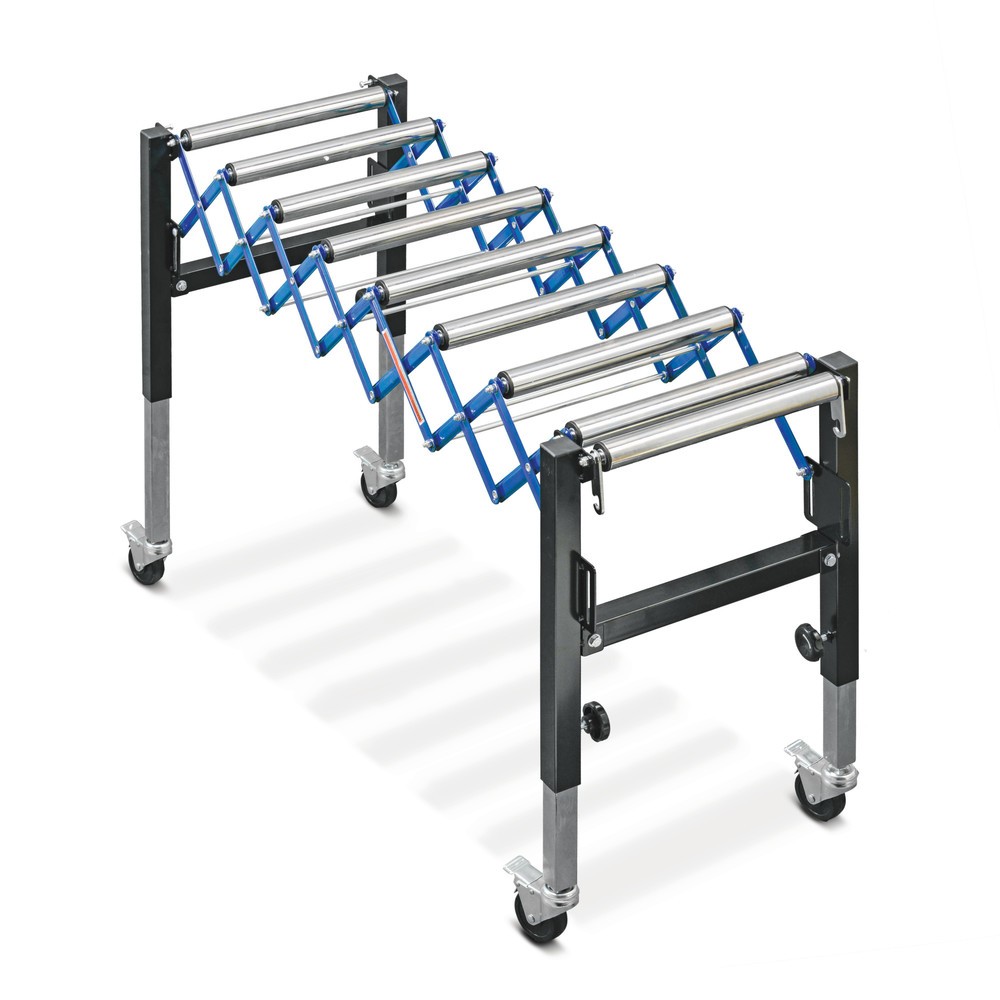

Accordion style roller conveyors (telescopic roller conveyors): the roller spacing on these designs can be adjusted to the size of the goods to be conveyed. |

Please note that depending on the extension length of a roller conveyor section, its maximum load capacity changes: the further apart the supports, the lower the maximum load capacity of the section.

2. Stationary or flexible roller conveyors

Conveyors with rollers can be set up as stationary or flexible, depending on the model and design. Which set-up variant is more suitable depends on where and to what extent you want to use them:

- Stationary roller conveyors: A stationary conveyor line makes sense if the type and dimensions of the goods to be transported do not vary and the route also remains the same. Stationary roller conveyors are also the right choice if the conveyor line is in permanent use.

- Flexible roller conveyors: With the help of flexible or extendable conveyor tables, you can adjust the conveyor line as circumstances require. This makes sense if the conveyor route changes frequently, or if branches or connections to workstations have to be built into the route from time to time. Flexible roller conveyors are also useful if they are only used occasionally and to transport goods over shorter distances.

Please note: The heavier the material to be conveyed, the larger the diameter of the rollers must be. Only in this way can the load be effectively moved along the conveyor line.

3. FAQ about roller conveyors

A roller conveyor (also called a roller conveyor table) works on the principle of gravity. The goods to be conveyed are transported from an elevated point to a lower end point with a gradient of 2% to 5% over the entire conveying distance.

Roller conveyor technology is useful wherever conveyed goods of the same type are transported from a starting point to a specific end point, sometimes having to cover longer distances in the operating areas or between different processing stations. For this purpose, the individual processing stations, such as packing stations, can be connected to each other via suitable roller conveyors or tables. If a motor-assisted drive is possible due to the slope or the spatial conditions, individual roller conveyor sections can also be connected to conveyor belts or other conveyor technology.

The goods to be conveyed should be placed in such a way that their long side points in the direction of transport. In addition, the goods should rest on at least three rollers at the same time so that the weight is optimally distributed among the rollers and sufficient and even rolling dynamics can be achieved over the gradient.